Enamel coil wire, also known as magnet wire or winding wire, is a vital component used in various electrical and electronic applications. Its superior electrical insulation properties, thermal conductivity, and mechanical strength make it an ideal choice for manufacturing coils used in transformers, inductors, motors, and other electrical devices. In this comprehensive guide, we will take an in-depth look at the manufacturing process of enamel coil wire, from raw materials to the finished product.

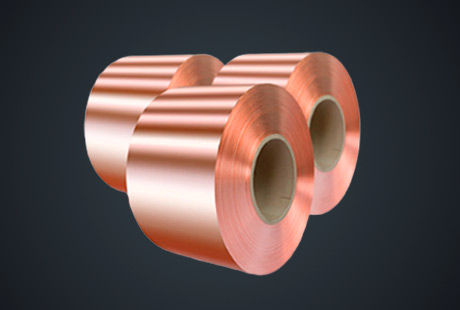

Selection of High-Quality Raw Materials

The manufacturing process of enamel coil wire begins with the careful selection of high-quality raw materials. The primary material used in enamel coated coil wire is copper due to its excellent electrical conductivity. However, different copper alloys may be used depending on the specific requirements of the wire. The enamel insulation is typically made from various polymer resins, such as polyurethane, polyester, polyamide, or polyimide, each offering different properties and temperature ratings.

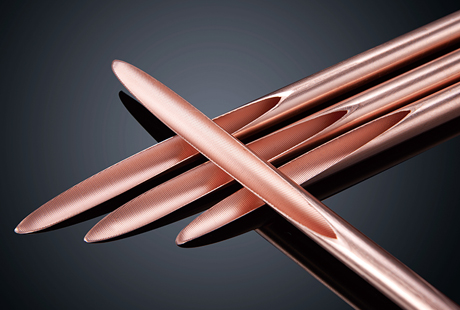

Wire Drawing

Wire drawing is the first step in the manufacturing process, where copper rods or wires are drawn through a series of dies to reduce their diameter to the desired size. This process not only imparts the required dimensions but also improves the copper's mechanical properties, making it suitable for further processing.

Enamel Coating Application

The next crucial step in the manufacturing process is the application of the enamel coating. The wire is passed through a series of guides and dies while being immersed in the enamel solution. The enamel coating is applied in a controlled manner to ensure a uniform and consistent thickness. Depending on the application, the wire may go through multiple enamel coating passes to achieve the desired insulation level.

Curing and Drying

After the enamel coating is applied, the wire is subjected to a curing process, also known as thermal treatment. The wire is passed through an oven or heated chamber at specific temperatures to cure the enamel and remove any solvents present in the coating. This curing process enhances the adhesion of the enamel to the copper conductor and imparts the necessary electrical and mechanical properties to the wire.

Testing and Quality Control

Throughout the manufacturing process, enamel coil wire undergoes rigorous testing and quality control measures. Various tests, such as spark tests, dielectric tests, and thermal class testing, are conducted to ensure the wire's insulation integrity and compliance with industry standards. Quality control checks also include measurements of diameter, insulation thickness, and mechanical properties to guarantee the wire's consistent performance and reliability.

The manufacturing process of enamel coil wire involves several critical steps, from selecting high-quality raw materials to the careful application of enamel coatings and stringent quality control measures. Each step is essential in ensuring that the enamel coil wire meets the required electrical, thermal, and mechanical specifications for its intended applications. As a fundamental component in electrical devices, enamel coil wire plays a vital role in modern technology, supporting the efficient functioning of motors, transformers, inductors, and various electronic components.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文