Electronic Connector

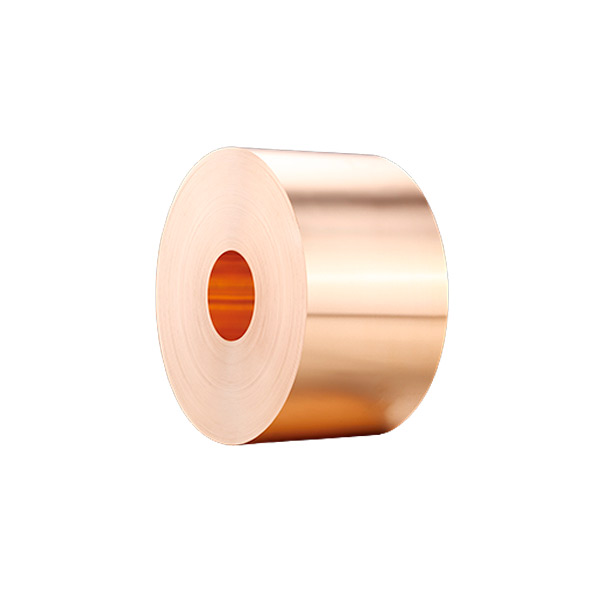

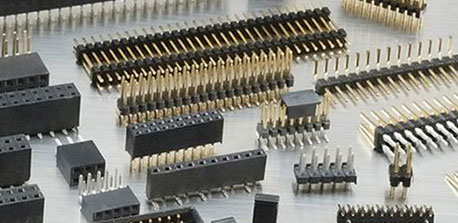

Phosphor bronze tape is widely used in electronic connectors due to its excellent electrical conductivity and mechanical properties. It ensures reliable electrical connections and low contact resistance, making it suitable for high-speed data transmission and signal integrity. The phos bronze strip's spring-like properties provide a secure and consistent contact force, maintaining a stable electrical connection even under challenging conditions.

Computer Connector

In computer connectors, such as those found in motherboards, graphics cards, and peripheral devices, phosphor bronze strip plays a vital role. Its high resilience and durability allow for repeated insertions and removals without compromising the electrical performance. The phosphor bronze tape's corrosion resistance ensures long-lasting connectivity, minimizing signal degradation and maximizing data transfer speeds.

Switch Socket

Phos bronze strip is extensively utilized in switch sockets due to its reliable electrical conductivity and wear resistance. The tin coating on the phosphor bronze tape provides additional protection against oxidation, ensuring prolonged durability and preventing contact failures. The tin phosphor bronze's spring properties enable smooth and responsive switch operations, making it ideal for various switch applications, including keyboards, industrial controls, and household appliances.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文