Mobile Phone Shield

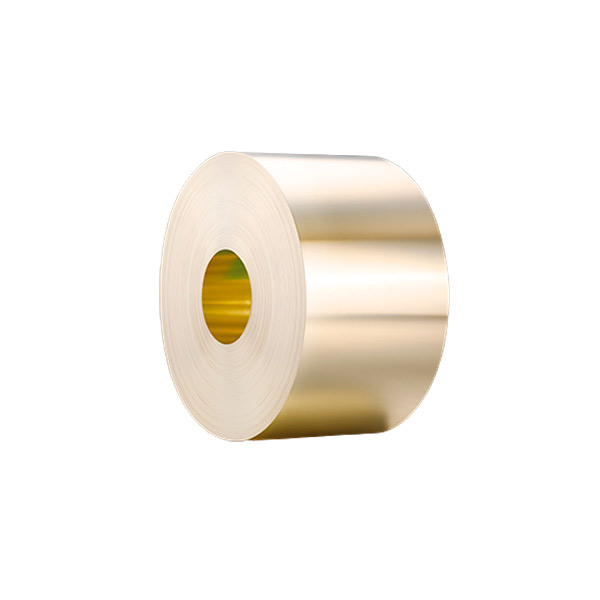

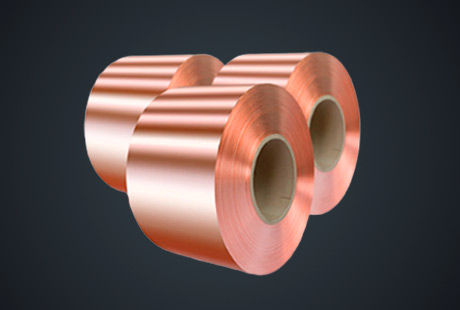

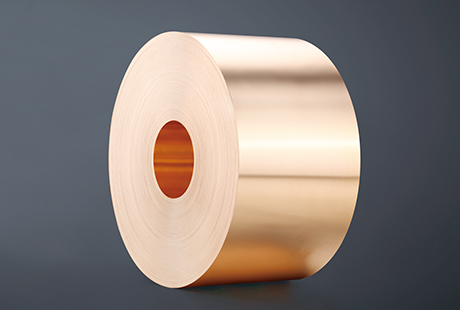

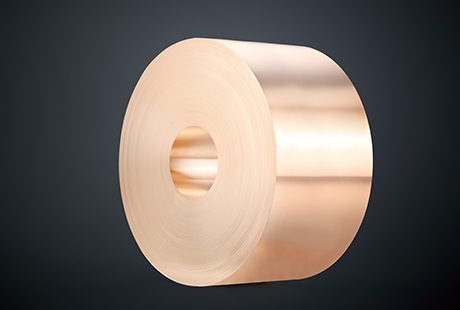

The excellent electrical conductivity and magnetic properties of nickel silver make it an ideal material for mobile phone shields. This silver metal strip is typically used to create a conductive enclosure around critical components such as circuit boards, chips, and antennas. This helps to prevent interference from external sources and ensures proper functioning of the mobile phone's communication systems.

Crystal Oscillator

Nickel silver coil strips are often used as the mounting or packaging material for crystal oscillators. The strips, like c7521 nickel silver strip provide mechanical support and protect the delicate crystal resonator inside the oscillator from external environmental factors. Additionally, the high electrical conductivity of nickel silver ensures proper signal transmission and minimizes signal loss, which is crucial for accurate timing and frequency control. Beyond high-quality nickel silver strips, Jintian offers a comprehensive selection including thin copper strips, leadframe strip, and more, to perfectly match your specific project requirements.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文