Copper And Copper Alloy Processing Materials Market For Power Transmission And Distribution And High-speed Rail

Copper and copper alloy processing materials are the earliest metal materials used by human beings. Because of their excellent physical properties and comprehensive performance, they are widely used in electric power, electronics, communications, rail transit, chemical industry, computer, light industry, instrumentation, daily hardware. , machinery manufacturing, construction engineering and military industries. Copper processed products can be divided into pipes, plates and strips (including copper bars), bars, wires and foils according to their shapes.

Among them, the output of copper wire accounts for the largest proportion, followed by copper plate and strip, copper pipe and copper rod, and the proportion of copper foil is relatively small. From the perspective of development speed, copper foil has the fastest development speed, with an average annual growth rate of 34%, but its scale is still small, and the growth rate of other sub-sectors is roughly the same, with an average annual growth rate of about 12%.

The fundamental feature of copper and copper alloy materials widely used in the field of engineering technology is that they belong to a relatively economical and practical conductive material. Pure copper has high electrical and thermal conductivity second only to silver, suitable strength, excellent corrosion resistance, easy brazing and deformation processing, and is widely used in the manufacture of various electrical wires and conductors. At the same time, with the improvement of people's living standards, the civil load continues to increase, and the power industry also shows a growing trend. With the introduction of building codes such as the configuration of residential wire diameters according to international standards, copper and copper alloy materials have provided copper and copper alloy materials in the power field. Broad development prospects.

Another feature of many types of copper alloy is that they have excellent alloying properties, and can form alloys with most of the current metal or non-metallic elements with their own characteristics. Product series to meet the needs of all walks of life. With the development of modern science and technology, its new alloy varieties used in the field of high and new technology continue to emerge, which represent the development direction of contemporary engineering materials and have broad development prospects.

Market Situation Of Copper Busbars And Copper Components In The Transmission And Distribution Industry

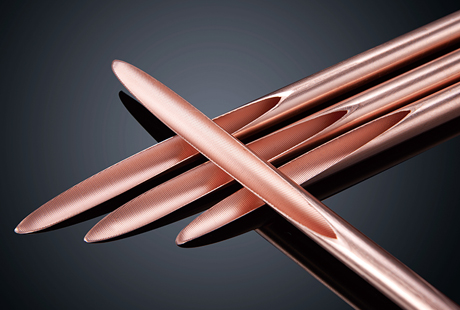

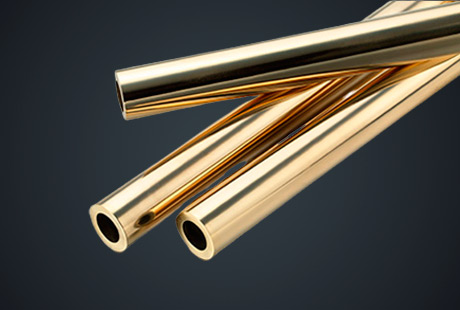

Copper and copper alloy busbars (hereinafter referred to as "copper busbars"), also known as copper busbars or copper busbars, refer to copper main conductors that play the role of collecting, distributing and transmitting electrical energy in power systems, usually made of copper or copper. The long conductor made of alloy material mainly plays the role of transmitting electric energy and connecting electrical equipment in electrical equipment. It is a high-current conductive product. Many copper busbars suppliers has provided high-quality products. The electrical copper bar has the advantages of low resistivity and large bendability, and is suitable for high and low voltage electrical appliances. , switch contacts, power distribution equipment, busbars and other electrical engineering, are also widely used in metal smelting, electroplating, chemical caustic soda and other super-current electrolytic smelting projects.

Copper busbar products are mainly intermediate products. The end user of copper busbar usually needs to reprocess the shape of copper busbar products. Therefore, most copper busbar products are made into rectangular cross-sections or chamfers (rounded corners) that are convenient for reprocessing. An elongated body of rectangular cross-section. However, some copper busbar manufacturers with strong processing capabilities can customize copper busbars with special shapes required by their customers. Shaped copper bar".

Copper busbars and copper components are mainly used in various transmission, distribution and power grid equipment, such as switch cabinets, busbars, circuit breakers and other high and low voltage electrical facilities, followed by motors and other power generation facilities to make motor windings Coils (copper busbars) and high and low voltage electrical switch contacts (shaped bars), as well as power supply and distribution installation connecting wires (copper bars) and other related electrical and electrical products. Developed countries such as Japan use new copper materials with high conductivity and high elongation to make motor winding coils and high and low voltage electrical switch contacts. The social demand for electricity increases, the construction of rail transit is accelerated, and the construction of high-rise buildings increases, so the demand for copper busbars will continue to increase.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文