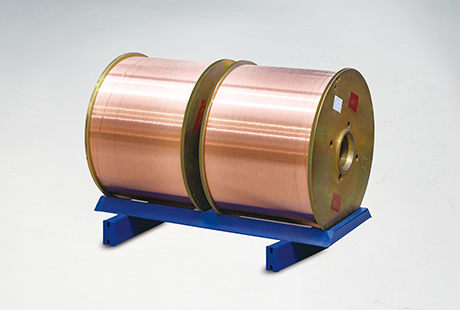

Annealed Copper Wire (2.6mm) Performance Advantages

Tinned annealed copper wire has several performance advantages over other types of wire:

Flexibility

Annealed copper wire is more flexible than non-annealed wire. This makes it easier to bend and shape into the desired form, which is especially useful for applications that require intricate or complex shapes.

Resistance to Fatigue

Annealed copper wire is more resistant to fatigue than non-annealed wire. This means that it can withstand repeated bending and twisting without breaking or cracking.

Conductivity

Copper is an excellent conductor of electricity, and annealed copper wire is no exception. This makes it ideal for applications that require high conductivity, such as electrical wiring, motors, and transformers.

Ductility

Highly ductile features of annealed copper cable means that the wire can be drawn into thin wires without breaking. This makes it useful for applications that require fine wire, such as electronics and telecommunications.

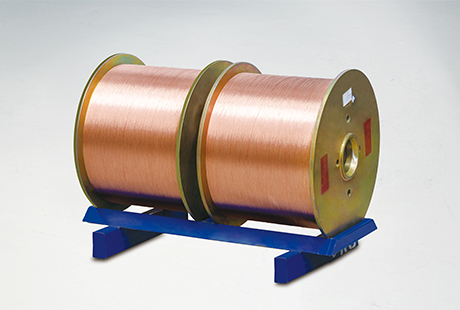

Enhanced appearance

Tinned annealed copper wire with a bright and smooth surface is aesthetically pleasing and enhances the appearance of the end product. no blurs. This is particularly important for applications where the wire is visible, such as in decorative lighting, jewelry, and other crafts.

Overall, annealed copper cable is a versatile material that can meet a wide range of technical requirements and specifications for fine lines, fine wires, and special products. Its excellent properties make it a popular choice for a variety of applications in different industries.

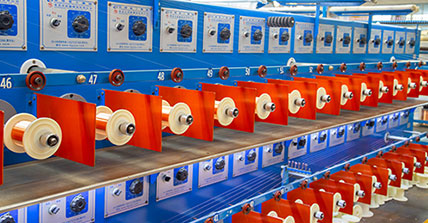

What is Copper Wire Annealing Process

Copper wire annealing process is a heat treatment process that is used to improve the ductility and conductivity of copper wire. During the annealing process, the copper wire is heated to a specific temperature and then cooled down slowly, in order to make the wire softer and more flexible.

The annealing process involves several stages, which include heating, soaking, and cooling. First, the copper wire is heated to a specific temperature, usually between 300°C and 800°C, depending on the desired properties of the wire. The wire is then held at this temperature for a period of time, which allows the metal grains to grow and become more uniform in size.

Next, the wire is cooled slowly, either by turning off the heat source or by placing the wire in a cooling chamber. This slow cooling process is essential, as it allows the metal grains to reform in a more regular pattern, which improves the wire's electrical conductivity and mechanical properties.

Annealed tinned copper is often used in the manufacturing of electrical components, such as transformers, motors, and generators, as it helps to improve the wire's electrical properties and make it more durable and reliable over time.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文