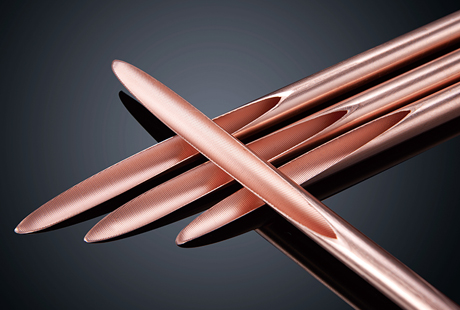

Enamel coated magnet wire, a crucial component in various electrical applications, has undergone significant advancements and innovations in recent years. Manufacturers such as Jintian Copper have been at the forefront of developing cutting-edge technologies in this field. In this blog, we will explore the latest trends and breakthroughs in enamel coated magnet wire technology, highlighting its benefits and versatile applications.

Introduction to Enamel Coated Magnet Wire

Enamel coated magnet wire, also known as magnet wire or winding wire, is a critical element used in electric motors, transformers, and various other electrical equipment. It typically consists of a conductive core, commonly made of copper, coated with a layer of insulation material. This insulation, usually a polymer-based enamel, protects the wire from external factors and enables efficient energy transfer within electrical systems.

Emerging Technological Developments in Enamel Coated Magnet Wire

With the constant drive towards energy efficiency and miniaturization, there have been numerous advancements in enamel coated magnet wire technology. One of the most notable innovations is the development of thinner coatings, allowing for greater packing densities and improved performance. Jintian Copper, for instance, has leveraged state-of-the-art manufacturing techniques to produce ultra-thin and uniform enamel coatings, pushing the boundaries of wire design.

Furthermore, advancements in nanotechnology have paved the way for enhanced insulation properties. Nanocomposite enamel coatings, incorporating nanoparticles, offer superior electrical and thermal resistance, making them particularly suitable for demanding applications in automotive, aerospace, and renewable energy industries.

Additionally, the introduction of self-bonding enamel coated magnet wire has revolutionized the assembly process. This type of wire eliminates the need for additional binding agents by integrating a self-adhesive enamel coating, resulting in time and cost savings during production.

Benefits and Applications of Enamel Coated Magnet Wire

Enamel coated magnet wire offers various benefits that contribute to its widespread usage in modern electrical systems. Firstly, its excellent electrical insulation properties ensure minimal energy loss during transmission, resulting in higher efficiency and reduced power consumption. Additionally, the insulation layer protects the wire from environmental factors such as moisture, dust, and heat, ensuring optimal performance and longevity.

The versatility of enamel coated magnet wire enables its application in a wide range of industries. It is employed in electric motors and transformers for efficient energy conversion, noise reduction, and improved overall performance. The automotive sector benefits from its utilization in ignition systems, control units, and sensors, where reliability is paramount. Furthermore, enamel coated magnet wire finds applications in renewable energy systems, where its high thermal conductivity and insulation properties are crucial for the efficient generation and distribution of power.

The enamel coated magnet wire industry has witnessed remarkable advancements and innovations, driven by the need for more efficient and reliable electrical components. Manufacturers like Jintian Copper have pushed the boundaries of wire technology, developing ultra-thin coatings, nanocomposite materials, and self-bonding options. These breakthroughs have resulted in enhanced performance, increased energy efficiency, and expanded applications across various industries. As the demand for advanced electrical systems continues to grow, enamel coated magnet wire will play a pivotal role in shaping the future of technology.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文