In today's rapidly evolving world, technological advancements are taking place in practically every industry, and the metals industry is no exception. This holds true for the leaded brass rod sector as well. Leaded brass rod finds its applications in a variety of industries due to its unique properties and versatility. In this blog, we will explore the latest innovations and advancements shaping the leaded brass rod technology today.

The Significance of Leaded Brass Rod

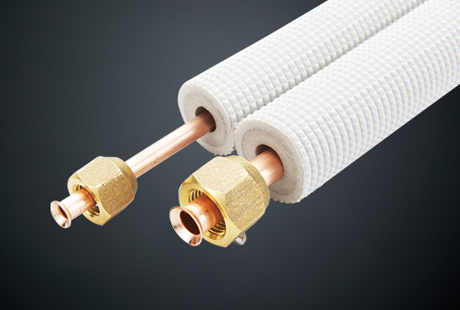

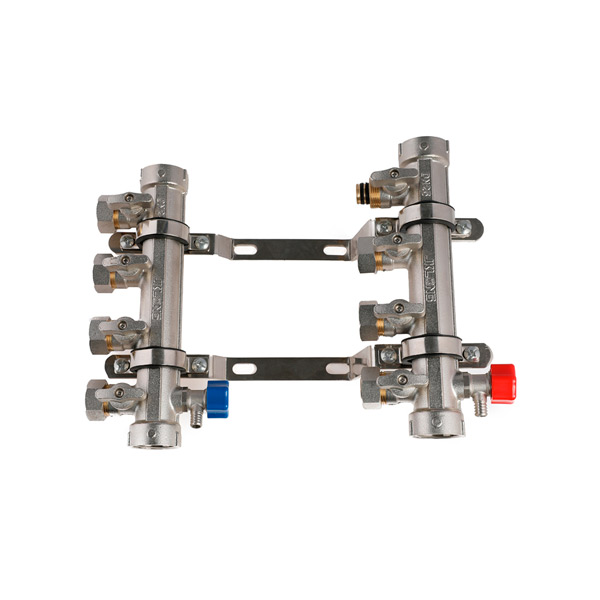

Leaded brass rod is a type of brass alloy that incorporates a small amount of lead, which enhances machinability and makes it an excellent choice for various applications. Its ability to resist corrosion, excellent electrical conductivity, and thermal properties make it highly desirable in the manufacturing sector, plumbing industry, electronics, and others. The versatility and functionality of leaded brass rod have led to continuous research and development to enhance its properties further.

Advances in Production Techniques

With advancements in manufacturing processes, the production of leaded brass rod has become more efficient and cost-effective. Traditional methods such as continuous casting have been improved to ensure higher quality and consistency in the final product. Additionally, the implementation of computer-controlled technology in the production process has allowed for precise control of alloys and better customization options, meeting specific industry requirements.

Alloys and Composition

Further innovations in leaded brass rod technology aim to enhance its mechanical properties, machinability, and overall performance. By precisely controlling the composition of the alloy, manufacturers are now able to achieve desirable features like improved tensile strength, corrosion resistance, and thermal stability. These advancements allow leaded brass rod to meet the high standards set by industries such as automotive, aerospace, marine, and electrical.

Research and Development in Lead-Free Alternatives

While leaded brass rod continues to play a vital role in various industries, the negative environmental impact associated with lead has led to increased research and development in lead-free alternatives. Innovators and scientists are exploring various compositions and alloys to create lead-free brass rods that can deliver comparable performance and meet the growing demand for sustainable solutions. These advancements could potentially replace traditional leaded brass rods in the future, without compromising on quality and functionality.

The leaded brass rod industry is witnessing significant advancements and innovations that have paved the way for improved performance, enhanced mechanical properties, and better customization options. With the evolving manufacturing processes, the production of high-quality leaded brass rods has become more efficient and cost-effective. Furthermore, ongoing research and development efforts are focusing on lead-free alternatives, reflecting the industry's commitment to sustainability. As technology continues to progress, it is exciting to envision the future of leaded brass rod technology and its potential contributions to various industries.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文