In the modern world, where communication plays a pivotal role in our daily lives, the efficient functioning of telecommunications systems is crucial. One critical component that is often overlooked but is essential for the smooth operation of these systems is annealed copper wire. In this blog post, we will explore the significance of annealed copper wire in telecommunications systems.

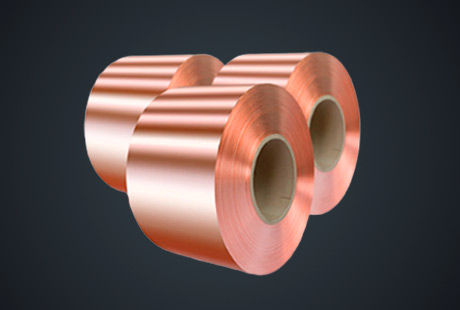

The Basics of Annealed Copper Wire

Annealed copper wire is a type of wire that has undergone a process called annealing, where it is heated and then slowly cooled to enhance its properties. This thermal treatment removes any stresses from the wire, making it more malleable and ductile, while also improving its electrical conductivity. The wire is typically formed into various gauges and shapes to cater to different telecommunications requirements.

Benefits of Annealed Copper Wire in Telecommunications Systems

Enhanced Conductivity

The primary advantage of using annealed copper wire in telecommunications systems is its exceptional electrical conductivity. Compared to other metals, such as aluminum, copper has superior conductivity, allowing for efficient transmission of signals with minimal resistance. This feature ensures high-quality and reliable communication.

Flexibility and Ease of Installation

Annealed copper wire's malleability and ductility make it easy to handle and install in telecom systems. Its flexibility enables it to be bent and shaped without breaking, offering greater design versatility and ease of installation. This characteristic is particularly valuable in complex networking structures and cable routing.

Applications of Annealed Copper Wire in Telecommunications Systems

Telecommunication Cables

Annealed copper wire serves as the core conductor in telecommunication cables. It provides the main pathway for transmitting voice, data, and video signals across various networks. Due to its conductivity and durability, copper wire ensures that the signals reach their destinations with minimal disruption or degradation.

Connectivity Solutions

Annealed copper wire also plays a vital role in connectivity solutions within telecommunication systems. From connectors, terminals, and jacks to circuit boards and interconnecting cables, annealed copper wire enables the seamless integration of different components, facilitating efficient signal transfer and reducing signal loss.

Ensuring Quality and Reliability with Annealed Copper Wire

To maximize the benefits of annealed copper wire in telecommunications systems, it is crucial to ensure its quality and reliability. Here are some key considerations:

Source from Trusted Suppliers

Choosing a reliable supplier that adheres to strict quality control standards is paramount. This ensures that the annealed copper wire used meets the required specifications and standards for optimal performance.

Regular Maintenance and Inspection

Periodic maintenance and inspection of the telecommunications systems, including the annealed copper wire, help identify any issues or potential points of failure. Timely detection and remediation can prevent costly downtime and disruptions in communication services.

Upgrading and Future-proofing

As technology continually advances, it is essential to keep up with the latest developments in telecommunication systems. Upgrading to newer generations of annealed copper wire, which may offer improved conductivity and durability, can enhance the performance and longevity of the systems.

Annealed copper wire is an indispensable component in telecommunications systems. Its excellent electrical conductivity, flexibility, and ease of installation make it an ideal choice for transmitting signals efficiently. By understanding the benefits and applications of annealed copper wire and taking necessary measures for quality assurance, telecommunication service providers can ensure reliable and seamless communication for their customers. If you require annealed copper wires, please feel free to contact us, JTCOPPER. Jintian Copper is recognized as one of the foremost professional annealed copper wire suppliers in China. With a commitment to excellence, Jintian Copper stands out for its dedication to delivering high-quality annealed copper wire products. As a leading supplier, they combine expertise with top-notch manufacturing practices to provide reliable solutions tailored to meet diverse industry needs.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文