Both the flaring and expanding of the copper pipe may lead to the cracking of the copper pipe of the air conditioner. In the production process, the flaring and expanding of the copper pipe belong to a continuous production process, which is generally combined into one process. In-depth analysis can be found that the quality of the copper tube itself and improper use by users may cause the copper tube to crack.

Cracking of copper AC tubing

There are many reasons for the cracking of the copper AC tubing, the main reasons are as follows:

1. The reason for the quality of the copper AC tubing itself

The reasons for the quality of the copper AC tubing itself can be divided into outer surface defects, inner surface scratches, and inner surface oxidation.

During the cold working deformation of expanding and flaring, the surface of the copper AC tubing is stretched by tensile stress. When there are deep scars on the outer surface of the copper AC tubing, the outer surface of the copper AC tubing cannot bear the surface tensile stress, resulting in the phenomenon of pulling and breaking. It is the cracking on the outer surface of the copper pipe of the air conditioner that we see.

The cracking mechanism caused by the scratch on the inner surface of the copper pipe of aircon copper pipe suppliers is similar to the cracking mechanism caused by the scratch on the outer surface. When the inner surface of the copper AC tubing is oxidized, the friction force on the inner surface of the oxidized copper pipe is not equal to the friction force on the inner surface of the non-oxidized copper AC tubing, resulting in inconsistent lengths and dimensions of the lower piers of the same length of air-conditioning copper pipes fittings. At the time of opening, the copper AC tubing with a small amount of lower piers has a long extension, resulting in excessive flaring and cracking.

2. Reasons for the use of the copper AC tubing by users

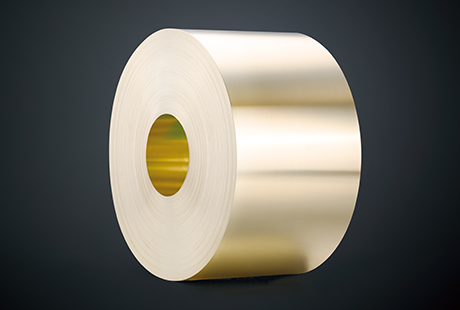

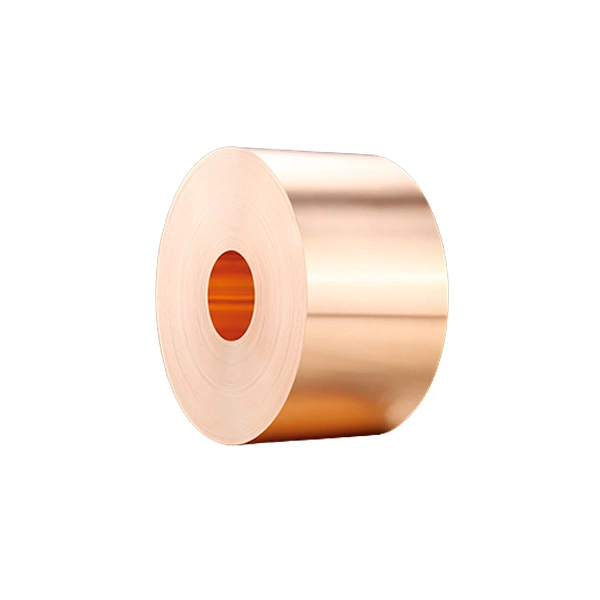

In the use of the copper AC tubing, pancake coils are often straightened and cut to length, and chip-free cutting is often used for cutting.

The surface of the copper AC tubing is relatively soft after heat treatment. During chip-free cutting, when the cutter is unfavorable or the lower knife is too large during cutting, it will cause the copper AC tubing to shrink too much or have too many burrs, resulting in port flash and port hardening, resulting in expansion. Cracks in the mouth.

A heat exchanger consists of many "U"-shaped tubes. The length of each "U"-shaped tube and the length of the two ends of each "U"-shaped tube are very consistent. When bending the "U"-shaped tube When the length of each "U"-shaped pipe and the length of the two ends of each "U"-shaped pipe are too different (more than 2mm) due to the equipment or adjustment, the copper pipe due to the excessively long port will appear when expanding. The extension length is too long, causing the flaring to be too large and cracking.

3. The reasons of aircon copper pipe suppliers

Common copper tube cracking is affected by the defects of the supplier's product itself or the customer's processing process. There are also some cracking factors such as: unreasonable copper tube design tolerance, copper tube mechanical properties and processing methods do not match and other factors that need attention.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文