With the increasing demand for reliable plumbing systems, the choice of copper tubing plays a crucial role in ensuring a successful installation. Jintian Copper, a renowned brand in the industry, offers high-quality Type L and Type M copper tubing. In this blog post, we will delve into the installation techniques specific to these copper tubing types. By understanding their differences, learning the proper handling and preparation techniques, and following a step-by-step guide, you can confidently install Type L and Type M copper tubing, assuring longevity and efficiency in your plumbing projects.

Understanding the Differences between Type L and Type M Copper Tubing

Type L Copper Tubing

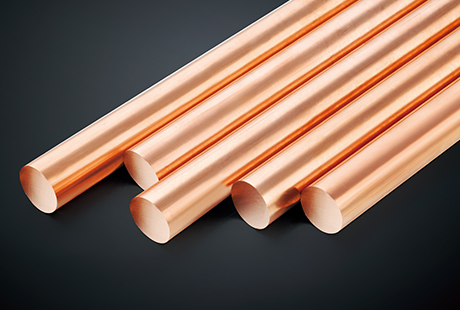

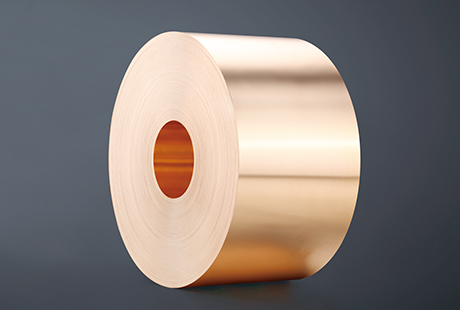

Type L copper tubing, known for its resilience and durability, is commonly used in both residential and commercial plumbing projects. Featuring a medium wall thickness, it strikes a balance between strength and flexibility. This makes it suitable for various applications, including water supply, heating, and cooling systems. The letters "L" represent the lightest wall thickness in the copper tubing family, making it economical and easier to handle during the installation process.

Type M Copper Tubing

Type M copper tubing, on the other hand, is favored for its affordability and ease of installation. With a thinner wall compared to Types K and L, it is best suited for low-pressure systems, such as residential plumbing lines and refrigerant lines. While it may not be as durable as Type L copper tubing, its lower cost and flexibility make it an attractive choice for budget-conscious projects. However, it's important to assess the required pressure levels and system specifications before opting for Type M copper tubing to ensure longevity and avoid potential leaks.

Proper Handling and Preparation for a Successful Installation

Type L and Type M Copper Tubing Preparation

Before embarking on the installation process, it is crucial to properly handle and prepare the Type L and Type M copper tubing. Start by storing the tubing in a clean and dry area, protecting it from stress, moisture, and excessive heat. Check for any bends, kinks, or damage that may affect the tubing's integrity and performance. Next, clean the ends of the tubing thoroughly using a wire brush or emery cloth to remove any debris or contaminants. Finally, ensure that you have the necessary tools and fittings required for a seamless installation.

Step-by-Step Guide to Installing Type L and Type M Copper Tubing

Measure and Cut

Begin by accurately measuring the required length of the copper tubing, keeping in mind any allowances for fittings or bends. Use a tubing cutter specifically designed for copper tubing to achieve clean and precise cuts. Remember to deburr the cut edges to avoid damage to the fittings and ensure a leak-free connection.

Flare or Solder

For Type L copper tubing, using a flare connection is recommended. Follow the manufacturer's instructions to properly flare the tubing ends and securely attach the fittings. In the case of Type M copper tubing, soldering is typically employed. Take extra care when soldering, ensuring a tight joint without excessive heat that could compromise the tubing.

Install and Secure

Now, carefully insert the flared or soldered ends into the corresponding fittings, ensuring a tight and secure connection. Use appropriate fittings, such as compression fittings, to prevent leaks. Pay attention to proper alignment and support the tubing adequately to avoid strain or sagging. For additional peace of mind, pressure test the installed copper tubing to identify any potential leaks before finalizing the installation.

By understanding the characteristics of Type L and Type M copper tubing, handling and preparing them correctly, and following a systematic installation process, you can ensure a successful plumbing project. Jintian Copper provides the high-quality materials necessary to achieve reliable and long-lasting results. With their dedication to quality and your attention to detail, you can confidently install Type L and Type M copper tubing, fulfilling both your plumbing needs and budgetary considerations.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文