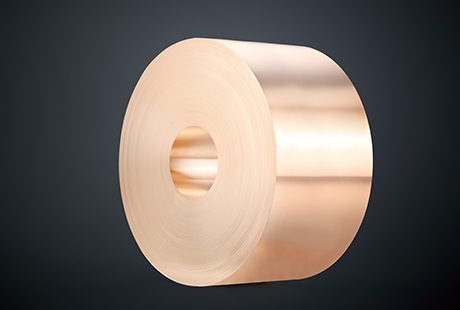

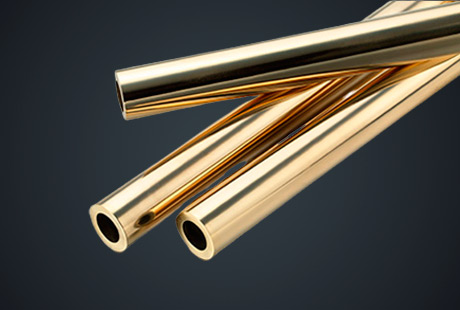

Enamelled copper winding wire is a type of wire that is coated with a thin layer of insulating material, typically made from polyurethane or polyester. The coating on the wire acts as an electrical insulator, allowing the wire to be wound tightly around a core without the risk of short circuits. This type of wire is a popular choice for a variety of applications due to its high performance and efficiency.

Enamelled copper winding wire is commonly used in the production of motors, transformers, and generators. It is also used in various types of electronic equipment, including televisions, radios, and computers. In the automotive industry, enamelled copper winding wire is used in the production of ignition coils, alternators, and starter motors.

The reason enamelled copper winding wire is popular in these applications is due to its superior electrical conductivity and insulation properties. The thin layer of insulation on the wire ensures that it does not come into contact with other conductive materials, reducing the risk of short circuits and increasing overall safety. Additionally, the high electrical conductivity of copper ensures that the wire can transfer electrical current efficiently, reducing energy loss and increasing the efficiency of the system.

Advantages of Enamelled Copper Winding Wire

Enamelled copper winding wire has many advantages over other types of wires, including its high electrical conductivity, thermal stability, and mechanical strength. The insulation coating on the wire also provides protection against abrasion, corrosion, and moisture, ensuring that the wire can be used in harsh environments without deteriorating.

Additionally, enamelled copper winding wire is environmentally friendly and can be recycled easily. Copper is a highly recyclable material, and recycling enamelled copper winding wire can reduce the need for mining new copper, reducing the carbon footprint and conserving natural resources.

Choosing the Right Enamelled Copper Winding Wire

When selecting enamelled copper winding wire for a specific application, it is essential to consider the wire's size, insulation type, and thermal class. The size of the wire should be selected based on the required current carrying capacity and the available space for winding the wire. The insulation type should be selected based on the environment where the wire will be used, as some insulation types may be more resistant to moisture or chemicals than others. The thermal class of the wire should be selected based on the expected operating temperature of the system, as the insulation coating may break down if exposed to temperatures beyond its thermal class rating.

In conclusion, enamelled copper winding wire is a high-performance and highly efficient choice for a variety of applications. Its insulation coating provides protection against short circuits, abrasion, and moisture, while its high electrical conductivity ensures efficient transfer of electrical current. Its versatility, mechanical strength, and thermal stability make it a popular choice in many industries, and its environmental benefits make it an environmentally friendly choice. When selecting enamelled copper winding wire, it is essential to consider the wire's size, insulation type, and thermal class to ensure optimal performance in the intended application.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文