Gas systems require secure and reliable connections to ensure the safe and efficient flow of gas. Copper gas press fittings have emerged as a revolutionary solution, offering seamless connections that transform gas systems. In this blog post, we will explore how copper gas press fittings revolutionize gas systems, providing benefits such as ease of installation, improved safety, and enhanced performance. Let's dive into the world of seamless connections and the impact of copper gas press fittings.

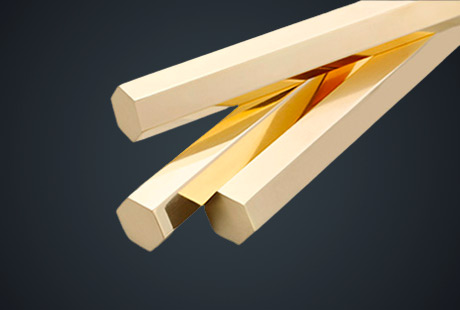

Understanding Copper Gas Press Fittings

Copper gas press fittings are innovative components designed for joining gas pipes without the need for soldering or welding. These fittings feature a unique press-connect technology that allows for quick and secure connections. They consist of a copper body with an integrated sealing element, ensuring a leak-free joint that withstands the demands of gas systems.

Simplified Installation Process

One of the key advantages of copper gas press fittings is their ease of installation. The press-connect technology eliminates the need for complex soldering or welding techniques. Installers can simply prepare the pipes, insert them into the fitting, and use a pressing tool to create a strong and reliable connection. This simplified installation process saves time and reduces labor costs, making it a game-changer for gas system installations.

Enhanced Safety and Reliability

Safety is paramount in gas systems, and copper gas press fittings prioritize this aspect. The secure press connection ensures a leak-free joint, minimizing the risk of gas leaks and potential hazards. The integrated sealing element provides a robust seal that withstands pressure and vibrations, ensuring long-term reliability. With copper gas press fittings, gas systems can operate with confidence, knowing that connections are secure and safe.

Versatility and Adaptability

Copper gas press fittings are highly versatile, suitable for a wide range of gas system applications. They can be used in residential, commercial, and industrial settings, accommodating different pipe sizes and configurations. Copper gas press fittings offer adaptability to diverse project requirements, enabling seamless connections in various gas system designs.

Improved Performance and Efficiency

Seamless connections provided by copper gas press fittings contribute to improved performance and efficiency in gas systems. The absence of solder or welding joints minimizes restrictions and turbulence, allowing for smoother gas flow. This enhanced flow reduces pressure drops and energy losses, optimizing the overall efficiency of the gas system. With improved performance, gas systems can deliver consistent and reliable gas supply.

Copper gas press fittings have revolutionized gas systems by offering seamless connections that simplify installation, enhance safety, and improve overall performance. With their press-connect technology, these fittings provide a secure and reliable joint, eliminating the need for soldering or welding. Installers benefit from time and cost savings, while gas systems enjoy improved safety, reliability, and efficiency. Embrace the seamless connections provided by copper gas press fittings and experience the transformative impact they bring to gas system installations.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文