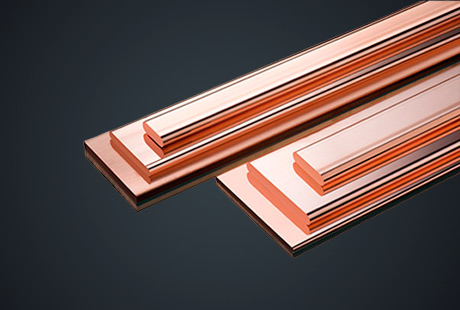

In engineering projects, precision is paramount. From electrical systems to advanced electronics, thin copper strips play a crucial role in enhancing design accuracy and performance. These versatile materials offer unique properties that contribute to the success of engineering projects. In this blog post, we will explore how thin copper strips enhance engineering projects by enabling precise designs and improving overall performance.

Electrical Conductivity and Efficiency

Thin copper strips are renowned for their exceptional electrical conductivity. This property makes them ideal for applications where efficient electrical transmission is essential. Whether in printed circuit boards, wiring harnesses, or power distribution systems, thin copper strips enable the seamless flow of electrical current, minimizing losses and maximizing efficiency. Their conductivity ensures that engineering projects deliver optimal performance.

Flexible and Space-Efficient Designs

The flexibility of thin copper strips opens up possibilities for intricate and space-efficient designs. Engineers can utilize the thinness and malleability of these strips to create complex patterns or routing paths in circuit boards and other electronic components. This flexibility allows for compact designs and optimized use of available space, making thin copper strips valuable in applications where size constraints are a concern.

Thermal Management and Heat Dissipation

Heat dissipation is a critical factor in engineering projects, especially in high-power applications. Thin copper strips excel in thermal management, thanks to their excellent thermal conductivity. They efficiently dissipate heat, helping maintain optimal operating temperatures in electronic devices and power systems. By utilizing thin copper strips as heat sinks or thermal pathways, engineers can improve the reliability and longevity of their projects.

Strength and Durability

While thin copper strips possess remarkable strength and durability. They can withstand mechanical stresses, vibrations, and environmental conditions, making them suitable for various engineering applications. The robustness of thin copper strips ensures the longevity and reliability of projects, even in demanding environments. Their resilience contributes to the overall performance and sustainability of engineered systems.

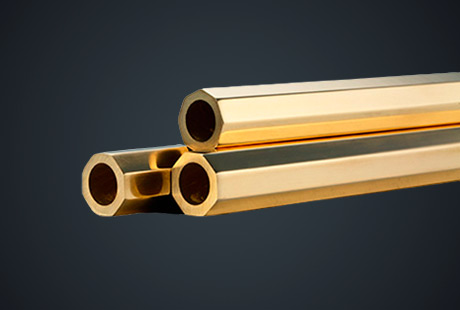

Versatility and Customization

Like brass stripes, thin copper strips offer versatility in design and customization. Engineers can easily shape, cut, or bend these strips to match specific project requirements. They can be tailored to precise dimensions and geometries, allowing for precise connections, interconnections, or complex circuitry layouts. This versatility empowers engineers to realize their design visions and optimize functionality in a wide range of engineering projects.

Thin copper strips are invaluable assets in engineering projects, enhancing design precision and overall performance. Their exceptional electrical conductivity, flexibility, thermal management capabilities, strength, and versatility make them indispensable in various industries. By utilizing thin copper strips, engineers can achieve efficient electrical transmission, optimize space utilization, manage heat effectively, ensure durability, and customize designs to meet project-specific needs. Incorporating thin copper strips in engineering projects opens doors to innovative and reliable solutions that drive technological advancements. Embrace the precision and advantages offered by thin copper strips to take your engineering projects to new heights.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文