Industrial motors generally refer to electromagnetic devices that realize the conversion or transmission of electrical energy through the electromagnetic induction law. Their main function is to generate driving torque, thus serving as the power source for electrical appliances or various machinery, with a relatively large proportion in motors.

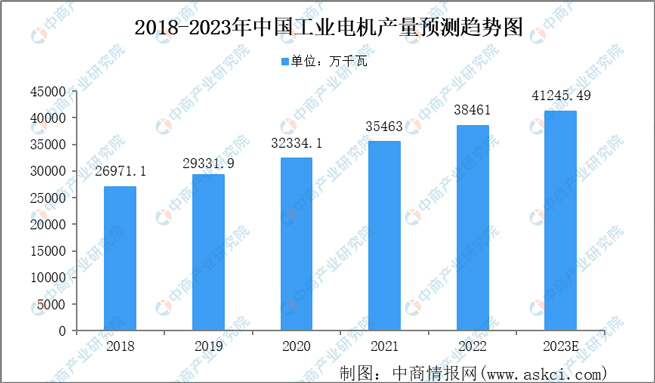

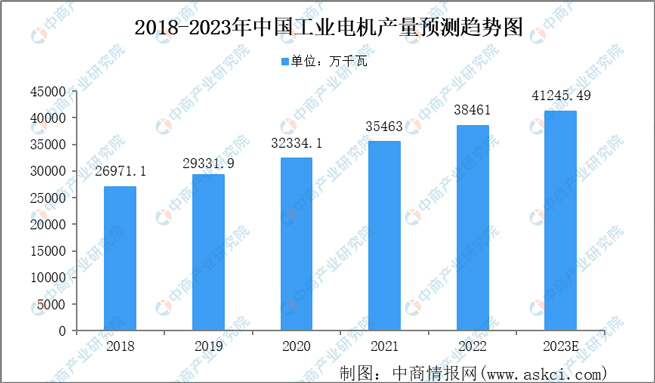

In recent years, with the promotion of policies in China, industrial motor manufacturing has been developing towards high efficiency and energy saving, and production has been continuously increasing. It is expected to reach 384.61 million kilowatts in 2022 and is expected to reach 412.45 million kilowatts in 2023.

According to different conditions, industrial motors can be divided into several types.

| Number | Classification | Type |

| 1 | Power supply | DC motor |

| AC motor |

| 2 | Structure and working principles | DC motor |

| Asynchronous motor |

| Synchronous motor |

| 3 | Starting and running mode | Capacitor-start single-phase asynchronous motor |

| Capacitor-run single-phase asynchronous motor |

| Capacitor-start-run single-phase asynchronous motor |

| Split-phase single-phase asynchronous motor |

| 4 | Application | Drive motor |

| Control motor |

| 5 | Rotor structure | Squirrel-cage induction motor |

| Winding rotor induction motor |

| 6 | Speed | High-speed motor |

| Low-speed motor |

| Constant-speed motor |

| Speed-regulating motor |

| Low-speed motor (gear reduction motor, electromagnetic reduction motor, torque motor, and claw pole synchronous motor) |

The main industrial motor manufacturers are mainly focused in Jiangsu, Zhejiang, Shandong, Guangdong, and other regions, accounting for about 50% of the market. In terms of competition, the current situation of industrial motors in China mainly lies in product technical content, price, level of automation of manufacturing equipment, and production scale. In terms of enterprise competition pattern, the mid-to-high-end market of industrial motors is mainly dominated by foreign industrial motor manufacturers such as Siemens and ABB, which have rich experience and mature products. Local leading manufacturers such as Huichuan, Delta, and Wolong focus on the high-end market and some mid-range markets. The low-end market is mainly dominated by small and medium-sized enterprises.

| China's industrial motor competition pattern |

| Tier | Enterprise Name | Basic Situation | Main Market Layout |

| First tier | Siemens, ABB, etc. | Rich experience, mature products | High-end, mid-range |

| Second tier | Wolong Electric Drive, Deyang Motor, Hitachi, Toshiba | Focus on different production fields | High-end, some mid-range markets |

| Third tier | Local small and medium-sized enterprises | Low prices, poor stability | Low-end market |

Jintian Copper is one of the few companies in the world that manufactures both enameled wires and rare earth aluminum iron boron. It produces direct weldable polyurethane enameled copper round wire QA (UEW), nylon composite enameled wire QA/N (UEW/N), polyester enameled copper round wire QZ (PEW), polyesterimide enameled copper round wire QZY (EIW), polyesterimide/polyamide-imide composite enameled copper round wire Q(ZY/XY) (EI/AIW), anti-electric corona enameled copper round wire for variable frequency motors Q(ZY/XY)/200-BP, enameled copper flat wire Q(ZY/XY)(EI/AIWR/200), as well as low-grade magnetic steels (N series/M series/H series), high-grade magnetic steels (SH/UH/EH/AH series), double high-grade magnetic steels (high residual magnetism/high coercivity), magnetic steel components, etc. It has in-depth exchanges and cooperation with well-known motor manufacturers such as Siemens and ABB.

How to choose enameled wire for industrial motors?

Motor Power and Load

Determine the cross-sectional area and material of the enameled wire based on the motor's power and load. Generally speaking, the larger the power and the heavier the load, the thicker enameled wire is needed to withstand larger currents.

Working Environment

If the motor needs to work in high temperature, humid or corrosive environments, enameled wire that is resistant to high temperature, moisture, and corrosion needs to be selected.

Cable Length

The length of the cable also affects the transmission of current and power loss. Longer cables require thicker enameled wire to reduce power loss.

Safety Requirements

If the safety requirements for the motor are high, enameled wire that meets relevant safety standards, such as UL standards, should be selected.

Cost

Cost is also an important consideration, higher quality enameled wire generally has higher prices, so a reasonable choice should be made based on the actual situation.

Slot Fill Factor

Factors affecting slot fill include bounce angle of enameled wire, elongation rate, surface lubrication, and winding method.

Inter-turn Short Circuit of the Motor

Copper wire particles, hard masses, burrs, insulation, surface scratches or bruises, motor working environment, and temperature rise can cause inter-turn insulation damage and motor short circuit.

Taking various factors into consideration, the commonly used models for industrial motor winding wires in the current market include QZ/130, QZ/155, QZY/180, Q(ZY/XY)BP/200, with a size range of 0.3-1.5mm. The commonly used spool models are PT25, PT45, PT60, PT90, PT200. Welcome to purchase from Ningbo Jintian Copper. For inquiries, please contact us at 0574-83005999.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文