Transformers are composed of iron cores (or magnetic cores) and coils, and can be divided into the following categories based on the number of phases, cooling methods, and applications:

| Number of Phases | Single-phase transformers |

| Three-phase transformers |

| Cooling Methods | Dry-type transformers |

| Oil-immersed transformers |

| Applications | Power transformers |

| Instrument transformers |

| Test transformers |

| Special transformers |

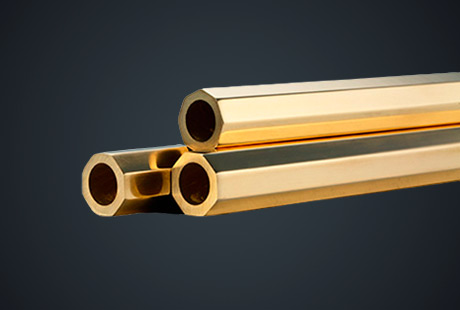

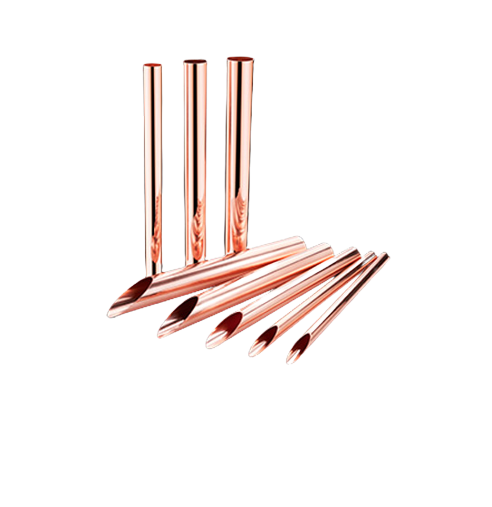

Copper busbars are conductors with very low resistance and are an indispensable part of transformers. They are used as wires that require large current supply. Transformer copper busbars are installed from the low-voltage side of the transformer to the power supply link between the power distribution cabinet, capacitor cabinet, and distribution cabinet. Although the transformer copper busbars are small, they play a very important role in transformers. Without transformer copper busbars, transformers cannot function properly.

| Copper Busbar Installation Types | Flat |

| Vertical (Note: slightly higher current carrying capacity than flat installation) |

How to Choose Transformer Copper Busbars?

Meet the current carrying capacity requirements.

Consider the rated current of the transformer with a 1.1 times overload factor.

Meet the safety distance and adapt to the component terminal.

Meet dynamic thermal stability. Note: If the low-voltage current of the transformer is 1000A, the design usually chooses a current density of about 1.8-2.2; for example, calculating based on 2, 1000/2=500, you can choose a 6*80=480 copper busbar; the general conventional transformer capacity is 30-2500kVA, and the low voltage of a 2500kVA transformer is around 3600A, 3600A/2=1800, you can choose a 120*15 copper busbar; if it is a high-capacity transformer, multiple copper busbars can be selected for parallel use.

Now Let's Take a Look at the Current Carrying Capacity Data of Different Copper Busbar Specifications

(1) Connection of upper and lower terminals of low-voltage isolation switch copper busbar requirements (consider the capacity of the main low-voltage incoming switch and the total capacity of the load carried by the isolation switch. If both are small and a larger isolation switch is still used, appropriate adjustments can be made)

| Copper Busbar Specifications | Current Carrying Capacity |

| TMY25*3 | 299A |

| TMY40*4 | 599A |

| TMY50*5 | 756A |

| TMY60*8 | 1160A |

| TMY80*10 | 1670A |

(2) Selection of main busbars for low-voltage transformers (excluding special customer requirements)

When selecting busbars, consider the related dimensions such as board-type joints and phase spacing! (Transformers below 50kVA can consider using cables instead of busbars as much as possible.)

(3) Selection of busbars for 10kV and 35kV box-type transformers according to the reference table

| Rated Current (A) | Breaking Current (KA) | Copper Busbar Specifications | Current Carrying Capacity |

| 630 | 20 | TMY-50*5 | 756A |

| 1250 | 40 | TMY-80*6 | 1300 A |

| 2000 | 40 | TMY-100*10 | 2030A |

| 3150 | 40 | TMY-125*8 | 3400A |

| Rated Current (A) | Breaking Current (KA) | Copper Busbar Specifications | Current Carrying Capacity |

| 630 | 20 | TMY-50*5 | 756A |

| 1250 | 25/31.5 | TMY-60*6 | 990 A |

| 1600 | 25/31.5/40 | TMY-100*8 | 1830 A |

| 2000 | 25/31.5 | TMY-125*8 | 2100A |

| 3150 | 25/31.5 | Dual TMY-125*8 | 3400 A |

| 4000 | 40/50 | Dual TMY-125*8 | 4100A |

Considerations for Selecting Copper Bars for Transformers

Current Capacity

It varies with changes in ambient temperature.

Maximum Short Circuit Current

This involves considering the size of the short circuit current when selecting a specific copper bar size. This helps in matching the appropriate protection (such as fuse or relay protection values) for instances where a short circuit occurs at the farthest point.

Jintian Copper is a professional manufacturer of copper bars, capable of producing various types including T2 copper bars, TMY copper bars, special-shaped copper bars, and coiled bars. For inquiries, please contact us at 0574-83005999. We welcome custom orders.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文