Leaded brass rod and lead-free copper rod are two important material types in the field of copper processing, with significant differences in performance, applications, and environmental friendliness. This article aims to delve into the characteristics, advantages, limitations, and respective application areas of these two types of copper rods, providing a comprehensive and professional comparative analysis.

Basic Knowledge

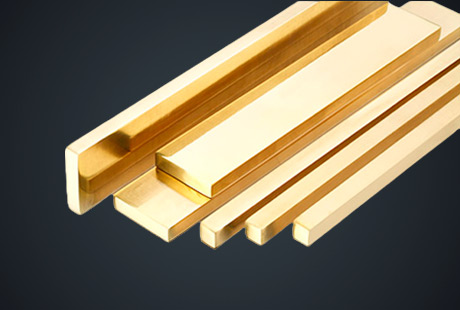

Definition and Characteristics of Leaded Brass Rod

Leaded brass rod is a type of brass containing lead, with copper, zinc, and lead as its main components. The addition of lead can improve the material's cutting performance, making it more suitable for mechanical processing. Leaded brass has good corrosion resistance, wear resistance, and relatively high strength, but the presence of lead also limits its use in certain applications, especially in areas involving food safety and drinking water safety.

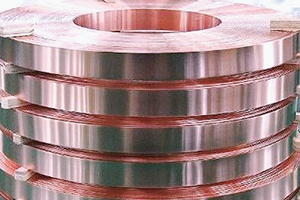

Definition and Characteristics of Lead-Free Copper Rod

As a reliable copper rod manufacturer, we also provide lead-free copper rod. In line with its name, lead-free copper rod is copper material that does not contain lead. These materials usually contain other alloying elements such as silicon, manganese, and aluminum to improve their performance. Lead-free copper rods retain the basic properties of copper, such as good conductivity, thermal conductivity, and corrosion resistance, while alloying enhances mechanical strength and processing performance. Lead-free copper rods are more in line with current environmental requirements, especially suitable for areas with strict limits on lead content.

Performance Comparison

Machining Performance

Leaded brass has better cutting performance due to the presence of lead, resulting in less wear during processing and longer tool life. While lead-free copper rods may lag slightly in machining performance, through alloy design and optimized heat treatment processes, their machining performance can also meet the requirements of most engineering needs.

Electrical and Thermal Conductivity

Copper is a well-known excellent conductor, and both lead-free copper rods and leaded brass rods excel in this aspect. However, the addition of lead may slightly decrease the material's electrical conductivity, although this effect is not significant.

Environmental Performance

Lead-free copper rods have a clear advantage in environmental performance. With increasing global emphasis on environmental protection and human health, the demand for lead-free materials is growing. Due to the presence of lead, the use of leaded brass rods is increasingly restricted, especially in areas where material safety is highly demanding, such as water systems and food processing equipment.

Application Area Comparison

Applications of Leaded Brass Rod

Leaded brass rods are mainly used in fields that require high cutting performance, such as machining of complex-shaped mechanical parts and components of precision instruments. However, due to environmental regulations, its application scope is gradually narrowing.

Applications of Lead-Free Copper Rod

Due to its excellent environmental characteristics and overall performance, lead-free copper rods are widely used in multiple fields. This includes electrical industry components, connectors, switchgear, as well as automotive industry radiators, cables, and brake system components. In addition, lead-free copper rods are the preferred materials for water systems (such as pipes and valves), medical equipment, and food processing equipment, as these applications have strict requirements for material safety.

Performance Improvement and Environmental Challenges

Impact of Technological Innovation on Performance

With the advancement of materials science, the performance of lead-free copper rods is continuously improving through various alloy designs and heat treatment processes. These technological innovations not only improve the mechanical and processing performance of lead-free copper rods but also enable them to surpass traditional leaded brass rods in specific applications.

Influence of Environmental Regulations on Material Selection

Global emphasis on environmental protection has led to strict control over the use of hazardous substances, with lead being a harmful heavy metal subject to significant restrictions in products. Regulations such as the RoHS (Restriction of Hazardous Substances Directive) and the Safe Drinking Water Act in the United States impose strict limits on the use of lead. This has promoted the development and application of environmentally friendly materials such as lead-free copper rods.

Future Prospects

Market Trends

With the increasing awareness of environmental protection and the implementation of relevant regulations, the market demand for lead-free copper rods is expected to continue to grow. Meanwhile, although there is still demand for leaded brass rods in certain specific areas, its overall market share may gradually decrease.

Research and Development Directions

Material research and development will focus more on balancing environmental protection and performance, further enhancing the performance of lead-free copper rods through material alloying, surface treatment technologies, and expanding their applicability in high-end application areas. Meanwhile, for leaded brass, research and development efforts may focus on finding alternative alloying elements to replace lead to meet both environmental and performance requirements.

Conclusion

Leaded brass rods and lead-free copper rods play important roles as materials with different characteristics and application areas. With technological advancements and the implementation of environmental regulations, the application scope and market demand for lead-free copper rods are expected to continue expanding. For the future development of copper materials, balancing environmental performance and material performance will be crucial. Jintian Copper will continue to strive to ensure material performance while meeting increasingly strict environmental requirements, contributing to sustainable development.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文