In new energy vehicles, the battery is an extremely crucial module and a key distinction from traditional fuel vehicles. It is well known that the arranging state of copper alloy is widely used in the battery connections of new energy vehicles, but few people understand the specific characteristics of this material. Now, let's have the editor reveal some knowledge about the copper busbars used in new energy vehicles.

First of all, in the battery system, the electrical connection used to connect the modules does not differ with the shape of the individual batteries.

There are generally 3 ways to connect battery modules.

First: Flexible Connection

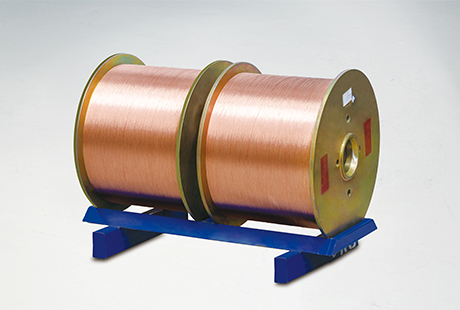

Flexible busbars are made by stacking multiple layers of corona-resistant flat thin copper sheets, and the outer layer is made using an extrusion method to cover an insulating layer. Generally speaking, flexible connections use 0.1mm copper strips as raw materials, which are cut according to the design requirements of the drawings.

If nickel sheets need to be attached to the contact surface at both ends, the customer needs to specify whether the entire strip should be nickel-plated or only partially. The cut raw materials are designed according to the drawing requirements, and according to the welding requirements, are formed by high-current high-temperature polymer diffusion welding.

The advantages of soft copper busbars are very obvious. From a performance perspective, multiple batteries are generally connected in series in the battery to obtain the corresponding working voltage. If a higher capacity current is required, to gain more power, two or more batteries can be considered to be connected in parallel.

The copper strip products produced by Jintian Copper fully meet the 0.1mm size requirements, have a flat surface, and excellent electrical conductivity, and are chosen as raw materials for flexible connections by domestic top-tier battery manufacturers.

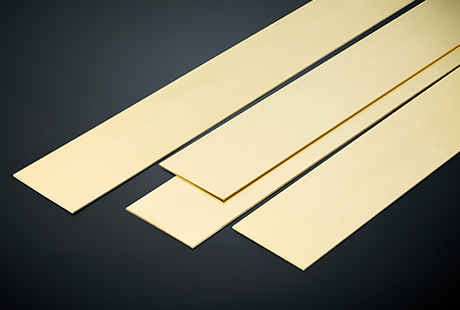

Second: Rigid Connection

Rigid connections, also known as hard busbars, are made of copper with a rectangular or chamfered (rounded corner) rectangular cross-section. This material is commonly made of copper and also aluminum, which is called aluminum busbar. They function in the circuit to deliver current and connect electrical equipment.

Copper busbar products made by Jintian Copper have excellent mechanical properties and weldability, can bear large currents, and can maintain stable performance under extreme conditions.

Third: Round Conductor

This solution is widely used in the industry, especially in the early stages of the development of battery module connection technology. But now many battery modules have abandoned this solution, mainly due to the spacing arrangement issues of the modules.

In terms of process, the processing technologies of soft copper busbars and rigid copper busbars are relatively not complex. However, in the industry, the entire process preparation, storage and placement of raw materials, packaging, and handling of finished products are relatively rough. With the booming development of the automobile industry, the site management and process levels of various raw material processing need urgent improvement.

Overall, the processing technology process of copper busbars is roughly as follows:

Standard material selection, cutting, pickling, slicing, welding, flattening, side cutting, punching, insulating outer layer, surface polishing, tin plating, packaging.

In terms of standards, copper busbars are widely used in the electrical industry. The main standards used in China are as follows:

GB/T5023 Insulated Cables Standard

GB7251-2008 "Low-voltage switchgear and controlgear assemblies"

GB5585.1-2005 "Busbar for electrical purposes" Part 1: Copper and copper alloy busbar The first part: Copper and copper alloy busbar

The main standards used abroad are as follows:

International Electrotechnical Commission IEC61439-1-2009 Low-voltage switchgear and controlgear assemblies. Part 1: General rules

International Electrotechnical Commission and IEC61439-1-2011 Low-voltage switchgear and controlgear assemblies. Part 1: General rules

UL67 recognition belongs to "panelboards and switchboards accessories used in the United States and Canada"

UL758 recognition belongs to "wiring materials - component" types 10531 and 11343 components

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文