Type K copper is a popular material used in plumbing systems due to its exceptional durability and resistance to corrosion. Its high copper content provides superior strength, making it ideal for both residential and commercial applications. In this blog post, we will delve into the maintenance and repair of Type K copper pipes, providing you with valuable insights to ensure their longevity.

Introduction to Type K Copper and its Importance in Plumbing Systems

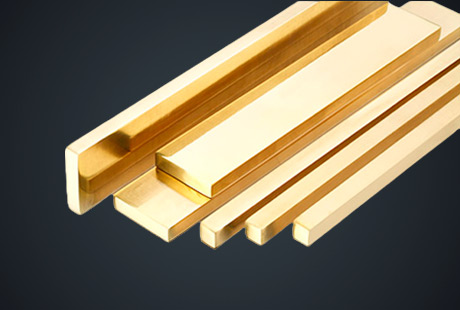

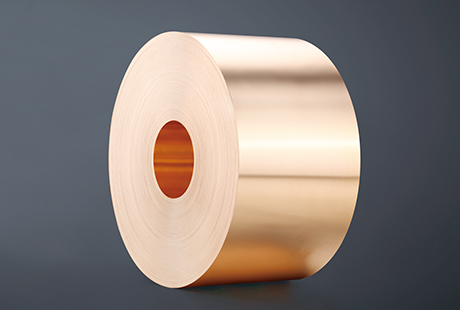

Type K copper is considered the heaviest and thickest among the four types of copper pipes, which include Type M, L, and DWV. Its thick walls enable it to withstand high pressures, making it suitable for carrying hot and cold water in various plumbing applications. Due to its resistance to corrosion, it is widely used in underground and exterior applications, ensuring a reliable water supply while minimizing the risk of leaks and failures.

Common Maintenance Techniques for Type K Copper Pipes

Inspection: Regularly inspect your Type K copper pipes for any signs of wear, corrosion, or leaks. Pay close attention to areas with high humidity or near heating sources. Look for discoloration, green spots, or pinhole leaks that may indicate underlying issues.

Protection: Prevent external damage to this type of copper pipe for sale by providing insulation or padding. This is especially important in areas prone to extreme temperatures, where insulation helps to control condensation and minimize potential damage caused by freezing and thawing cycles.

Water Quality: Maintain water quality by regularly testing for pH levels and mineral content. High levels of acidity or alkalinity in water can corrode copper pipes over time. Install suitable water treatment systems if necessary, such as water softeners or neutralizers.

Cleaning: Periodically clean the interior of Type K copper pipes to remove any mineral deposits or buildup that may hinder water flow. Use mild solutions or natural remedies to avoid damaging the pipes. Consult with a professional plumber for recommended cleaning products.

Step-by-Step Guide on Repairing Type K Copper Pipes

Identify the Issue: Determine the location and cause of the pipe damage, whether it's a minor leak, pinhole, or split. Ensure the water supply is turned off before proceeding.

Remove the Damaged Section: Cut out the damaged portion using a pipe cutter or hacksaw, making straight and clean cuts. Smooth the cut edges with sandpaper or a pipe reamer to ensure a proper fit for the replacement section.

Prepare for Soldering: Clean the ends of the existing pipe and the replacement section with emery cloth or a wire brush. Apply flux to the cleaned areas to promote solder adhesion.

Soldering: Use a propane torch and lead-free solder to join the replacement section with the existing pipe. Follow the manufacturer's instructions for proper technique and safety precautions.

Testing and Finishing: After soldering, allow the joint to cool and then turn on the water supply to check for any leaks. If the repair is successful, insulate the repaired section and ensure proper support to prevent strain on the pipes.

Maintaining and repairing Type K copper pipes is vital to ensure a robust and long-lasting plumbing system. Regular inspections, proper protection, and addressing issues promptly are key to avoiding costly repairs and water damage. By following the maintenance techniques outlined in this guide, you can preserve the integrity of your Type K copper pipes and enjoy a reliable plumbing system for years to come.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文