In the world of healthcare, precision, accuracy, and reliability are paramount. Medical equipment plays a pivotal role in diagnosing, monitoring, and treating patients, and the intricate web of components that make up this equipment must function flawlessly. One often-overlooked yet critical component in medical equipment is tinned copper busbars. In this article, we will delve into the vital role these busbars play in ensuring the seamless operation of medical devices, exploring their applications, benefits, and the significance of their use.

The Heart of Medical Equipment: Tinned Copper Busbars

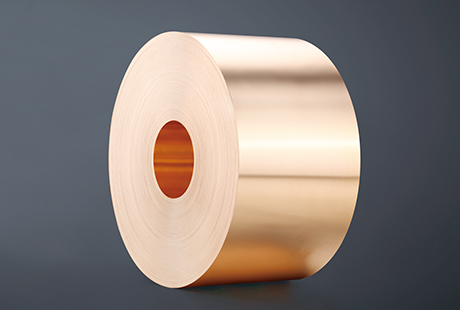

Tinned copper busbars are conductive components that serve as the electrical backbone of various medical devices, including MRI machines, CT scanners, patient monitoring systems, and more. These busbars are composed of high-quality copper, which is renowned for its excellent electrical conductivity. The tinning process involves coting the copper with a layer of tin, further enhancing its durability, corrosion resistance, and solderability.

Ensuring Precision and Reliability

Precision is critical in medical equipment. Whether it's an ECG machine monitoring a patient's heart rate or a blood analyzer providing crucial diagnostic data, the electrical connections within these devices must be stable and reliable. Tinned copper busbars offer just that.

The tin coating on these busbars not only protects against corrosion but also prevents the formation of undesirable copper oxides. This ensures that the electrical connections remain pristine and dependable, contributing to the consistent and accurate performance of medical equipment.

Reducing Downtime and Maintenance

In a healthcare setting, downtime and maintenance can have severe consequences. The use of tinned copper busbars minimizes the need for frequent maintenance and replacement of electrical components. Their robust design and corrosion resistance extend the lifespan of medical devices, reducing the risk of disruptions in patient care.

A Multitude of Applications

Tinned copper busbars find their way into a wide range of medical equipment. These applications include:

MRI Machines: The high electrical conductivity of tinned copper busbars ensures the rapid and precise transmission of data in MRI machines, enabling high-quality images for diagnostic purposes.

Patient Monitors: Patient monitors rely on stable electrical connections for accurate readings, and tinned copper busbars provide the necessary reliability.

Blood Analyzers: In blood analyzers, consistent electrical connections are vital for precise analysis and diagnosis.

Compliance with Regulatory Standards

The medical industry is highly regulated, and compliance with these standards is non-negotiable. Tinned copper busbars meet the stringent requirements of healthcare regulatory bodies, ensuring that the equipment they power adheres to industry standards for safety and accuracy.

In conclusion, tinned copper busbars are the unsung heroes of the healthcare sector. Their role in ensuring the precision and reliability of medical equipment cannot be overstated. By choosing the right electrical components, healthcare providers can offer their patients the highest quality care while minimizing downtime and maintenance costs. The next time you see an MRI machine or a patient monitor at work, remember that tinned copper busbars are playing a critical role in keeping things running smoothly and accurately.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文