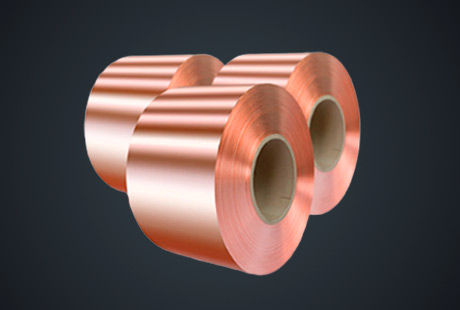

Copper is a versatile metal that is used in a wide range of industries for various applications. From electrical wiring to electronic devices, copper plays a crucial role in ensuring the smooth functioning of many products. One of the most common forms of copper used in these applications is rolled annealed copper foil, known for its excellent conductivity and flexibility. In this blog, we will explore the production process of rolled annealed copper foil, focusing on the brand Jintian Copper.

Raw Material Selection and Preparation

The production of high-quality rolled annealed copper foil starts with careful raw material selection and preparation. Jintian Copper sources copper cathodes that adhere to strict quality standards. These cathodes undergo rigorous testing to ensure they meet the required chemical and mechanical properties. Once selected, the copper cathodes are melted in a furnace and cast into large slabs. These slabs are then hot-rolled to reduce their thickness and lengthen them into coils for further processing.

Rolling and Annealing

Once the copper slabs have been hot-rolled into coils, they are ready for the rolling and annealing stages. The coils are first subjected to cold rolling, a process that gradually reduces the thickness of the copper while increasing its length. This step helps achieve the desired thickness required for the rolled annealed copper foil. Precise measurements and control systems ensure consistency in thickness and quality throughout the rolling process.

Following the cold rolling, the copper foil undergoes annealing. Annealing is a crucial step that involves heating the copper foil to a specific temperature and then slowly cooling it. This process helps relieve the internal stresses in the foil, making it more flexible and workable. Jintian Copper utilizes state-of-the-art annealing equipment to ensure that the rolled annealed copper foil achieves optimal electrical conductivity without any mechanical weaknesses.

Finishing and Quality Assurance

Once the rolled annealed copper foil has been completed, it goes through the finishing stage. This involves cleaning the foil to remove any impurities or residues that may have accumulated during the production process. Jintian Copper employs advanced cleaning techniques to guarantee a high level of cleanliness and surface quality. After cleaning, the foil is treated with appropriate coatings to protect it from corrosion and further enhance its performance.

To ensure the quality of its rolled annealed copper foil, Jintian Copper implements a rigorous quality assurance process. Samples from each production batch undergo extensive testing, including electrical conductivity, thickness measurement, and visual inspection. This thorough testing ensures that only top-quality rolled annealed copper foil is supplied to customers.

The production process of rolled annealed copper foil by Jintian Copper involves careful selection of raw materials, precision rolling and annealing, and thorough quality assurance. The resulting rolled annealed copper foil exhibits excellent electrical conductivity and flexibility, making it ideal for a wide range of applications. With Jintian Copper's commitment to quality and innovation, customers can trust in the reliability and performance of their rolled annealed copper foil.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文