With the rapid development of the automotive industry, the demand for high-conductivity alloys, high-strength and high-conductivity alloys, and high-conductivity heat-resistant copper alloys used in automotive electronic materials is also increasing rapidly. The original material supply monopolized by Europe, the United States, and Japan can no longer meet the fast-growing customer demands. Standing at the forefront of industry needs, JINTIAN integrates high-quality international supply chains to provide customers with premium C7025 copper alloy, which is well-received by customers.

What is C7025 Copper Alloy?

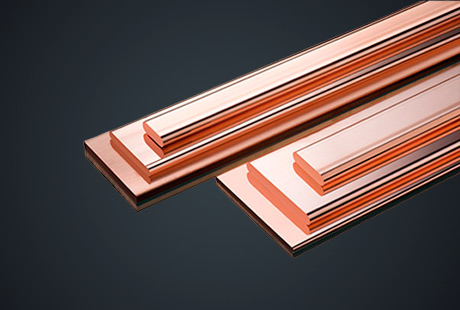

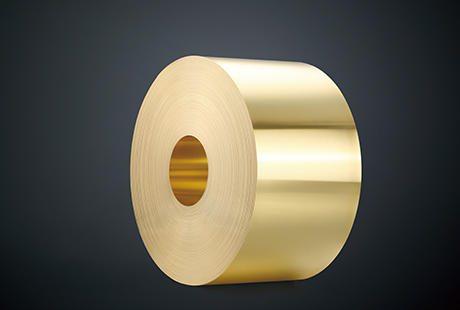

C7025 copper alloy is a high-strength, high-conductivity copper alloy, particularly effective when it undergoes temperature aging treatment in the latter stage of the alloy manufacturing process. This yields an effect similar to re-rolling, making the material harder and stronger, while also enhancing its conductivity and elongation. C7025 copper alloy, also known as silicon bronze, is a copper alloy containing nickel and silicon (also known as Si). It is a high-conductivity, high-elasticity alloy that doesn't require heat treatment, offering excellent stamping formability. It does not contain beryllium, making it economical and non-toxic. It features beautiful coloration, high electrical conductivity, good thermal conductivity, corrosion resistance, oxidation resistance, high strength, ductility, hardness, and fatigue resistance, as well as excellent platability and weldability. Due to its good forming properties, high resistance to stress relaxation, and moderate electrical conductivity, it is widely used for high-strength parts in relays, mobile phone components, and switches, and headphone jacks, serving as a replacement for low-beryllium-content beryllium copper. It is a foundational material for manufacturing integrated circuits and semiconductor discrete devices, mainly used in electronic appliances including integrated circuits, high-power diodes, measurement, LED brackets, communication equipment, test instruments, connectors, terminals, etc.

Chemical Composition of JINTIAN's C7025 Copper Alloy

Nickel (Ni): 2.2~4.2

Silicon (Si): 0.25~1.2

Magnesium (Mg): 0.05~0.3

Iron (Fe): ≤0.2

Lead (Pb): ≤0.05

Zinc (Zn): ≤1.0

Characteristics: JINTIAN's C7025 copper alloy features good yield strength and fatigue strength, excellent elasticity, excellent processing formability, and bending properties, good ductility, durability, and corrosion resistance.

Applications: Industrial electrical connectors, relays, stamped terminals, semiconductor lead frames.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文