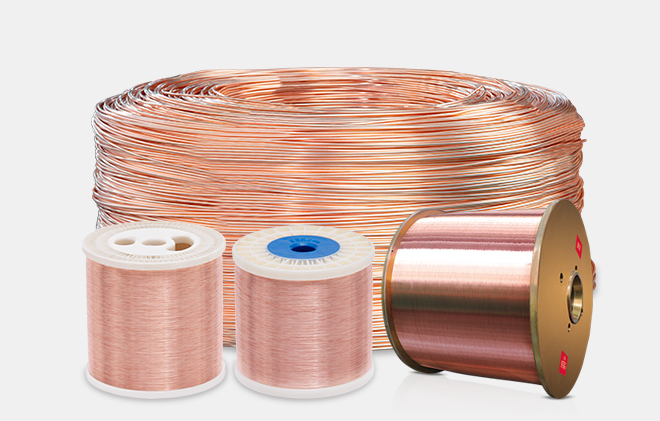

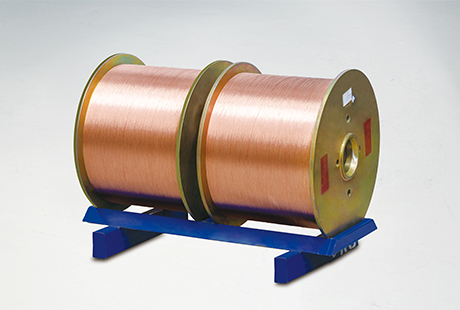

Submarine cables play a critical role in global communications, connecting continents and ensuring seamless transmission of data across vast distances. While many factors contribute to their reliability, one crucial element is the use of annealed copper wire. In this blog post, we will explore the numerous benefits of using annealed copper wire in submarine cables, highlighting its superior conductivity, durability, and environmental suitability.

Enhanced Conductivity for Efficient Transmission

Annealed copper wire possesses excellent electrical conductivity, making it the ideal choice for submarine cables. Its superior conductivity ensures minimal signal loss over long distances, enabling efficient transmission of data and voice communication. Compared to other materials, annealed copper wire consistently delivers high-quality signals, allowing for faster information exchange between continents.

Unmatched Durability for Longevity

Submarine cables are subjected to extreme environmental conditions, including high pressure, varying temperatures, and corrosive seawater. To withstand these harsh surroundings, annealed copper wire is manufactured to possess exceptional strength and durability. Its robust construction enables it to resist degradation and remain intact even in challenging underwater environments. With annealed copper wire, submarine cables can withstand the test of time and provide uninterrupted connectivity for decades.

Resistance to Damage and Breaks

In submarine cable installations, the prevention of damage or breaks is of utmost importance. The flexibility and strength of annealed copper wire make it highly resistant to external forces that can potentially cause fractures or faults in the cable. By utilizing annealed copper wire, submarine cable systems can minimize the risk of downtime and costly repairs, ensuring continuous communication between continents.

Environmental Suitability and Sustainability

As concerns for the environment grow, it is crucial to select materials for submarine cables that align with sustainable practices. Annealed copper wire is not only highly durable but also environmentally friendly. Copper is a widely available and recyclable material, making it a sustainable choice for the manufacturing of submarine cables. By opting for annealed copper wire, cable operators contribute to reducing their carbon footprint while maintaining optimal performance and reliability.

In conclusion, the utilization of annealed copper wire in submarine cables offers numerous benefits that directly impact their performance and longevity. Its exceptional conductivity ensures efficient transmission of data, while the wire's durability and resistance to damage guarantee seamless connectivity even in extreme conditions. Moreover, by choosing annealed copper wire, cable operators contribute to sustainable practices as copper is a recyclable material. As technology advances and the demand for global communication increases, the importance of using annealed copper wire in submarine cables cannot be overstated. Its remarkable qualities solidify its position as a reliable and efficient solution for transmitting data across vast distances.

As one of the Chinese annealed copper wire suppliers, we pride ourselves on meticulous craftsmanship, ensuring superior quality that is reliable. With leading technological capabilities, our products excel in performance, delivering high efficiency and stability. We are dedicated to providing heartfelt service, placing customer satisfaction as our top priority. Additionally, we are committed to green manufacturing, promoting low-carbon environmental protection, and fostering a sustainable future.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文