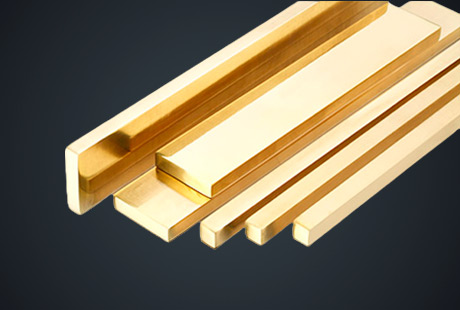

1. Copper strip is the field with the highest barriers in the copper processing industry

As an important downstream of the copper strip, the connector consumes a lot of strip material. As the chip carrier of the integrated circuit, the lead frame also belongs to the connector. It realizes the electrical connection between the lead-out end of the internal circuit of the chip and the external wiring by means of the bonding material, and acts as a bridge connecting the external wire.

In addition to high strength and high thermal conductivity, the application requirements of lead frame and manufacturing and packaging also require better brazing, stamping, etching and adhesion of oxide film particles. It is often made of copper-iron system, copper-nickel-silicon system C70250, etc.

2. Copper Cu-Ni-Si and Cu-Cr-Zr alloy strips belong to medium-high-strength and high-conductivity alloys

Copper beryllium (Cu-Be) can only be produced by Dongfang Tantalum in China, and Cu-Ti cannot be supplied by domestic companies. In particular, Cu-Ni-Si alloys have been widely used in the electronic field due to their excellent high temperature stability.

3. Copper-nickel-silicon alloy has excellent comprehensive performance, its permeability is improving, and it has great potential

The miniaturization of electronic products and the improvement of carrying capacity are obvious. In high-current connection occasions, such as base station power connectors, new energy vehicle connectors and smartphone connectors, high-conductivity copper-nickel-silicon alloys can suppress heat generation and temperature rise, and form a strong substitute for other types of copper alloy, such as brass, tin phosphor bronze, etc.

4. Copper automotive connectors have higher heat resistance than smartphones

The temperature environment inside the car: 120°C for the engine, 135°C for the engine surface, 120°C for the dashboard surface, 105°C for the interior floor, and 117°C for the rear deck. When a person rides in a car without air conditioning, the temperature inside the car can reach 120°C.

The use of brass and tin phosphor bronze for automotive connectors can no longer meet the requirements of use. It is necessary to use titanium copper or copper nickel silicon with better stress relaxation resistance.

China's copper processing industry has gone through three stages, and now it has entered the stage of high-performance materials represented by C7025. To meet the needs of industries such as communications, electronics and automotive upgrades.

5. The development of high-performance copper alloys in the future may have the following four directions:

(1) Double 70 alloy, tensile strength 700MPa, electrical conductivity 70%IACS, thickness 0.03-0.06mm;

(2) Environmentally friendly materials, tensile strength > 1000 MPa, yield strength > 950 MPa, electrical conductivity > 45 %IACS;

(3) Composite new materials, using the characteristics and advantages of various metal varieties, to achieve comprehensive performance improvement and cost optimization;

(4) Magnetic and conductive materials, CFA copper-iron alloy products, the general iron content is 15%-50%.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文