In the dynamic and challenging oil and gas sector, reliable and durable connections are crucial for the safe and efficient operation of pipelines, storage tanks, and other equipment. One such dependable connection method gaining popularity in the industry is solder ring joints. These joints, renowned for their exceptional sealing properties and long-term durability, are becoming increasingly prevalent in oil and gas applications requiring secure connections. In this article, we will delve into the dependability of solder ring joints in oil and gas operations and explore the various advantages they offer.

Understanding the Role of Solder Ring Joints in the Oil and Gas Sector

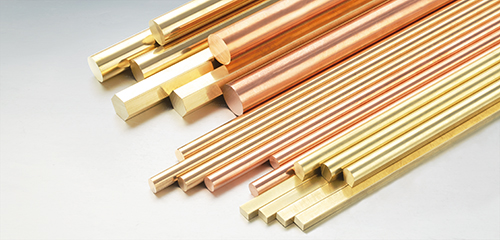

Solder ring joints, also known as capillary joints, play a vital role in the integrity of oil and gas installations. These joints are created by heating a solder ring to its melting point, allowing it to flow into the gap between two pipe connections, ensuring a watertight and gas-tight seal. This unique mechanism makes solder ring joints highly resistant to leakage, enhancing the overall safety and reliability of oil and gas systems.

Benefits of Solder Ring Joints in Oil and Gas Applications

Solder ring joints offer several advantages that make them an excellent choice for oil and gas applications. Firstly, these joints are quick and easy to install, significantly reducing the time and labor required for assembly. This characteristic is particularly valuable in the oil and gas industry, where time-sensitive operations are the norm.

Secondly, solder ring joints provide exceptional resistance to corrosion, especially in harsh environments often found in oil and gas operations. This resistance ensures that the joint remains reliable and durable over an extended period, contributing to the longevity and efficiency of oil and gas infrastructure.

Ensuring Reliability and Security with Solder Ring Joints

The reliability and security of connections in the oil and gas industry are of utmost importance to prevent potentially catastrophic accidents and environmental damage. Solder ring joints excel in providing a secure and leak-proof seal, minimizing the risk of hydrocarbon leakage and subsequent environmental contamination.

Additionally, solder ring joints exhibit excellent pressure resistance, making them suitable for high-pressure applications commonly encountered in the oil and gas sector. This feature ensures the joint's integrity and prevents any performance degradation even under extreme operating conditions, guaranteeing optimal safety and performance.

The Future of Solder Ring Joints in the Oil and Gas Industry

As the oil and gas industry continues to evolve and prioritize safety and efficiency, solder ring joints are expected to gain further prominence. The adaptability of solder ring joints to various materials, including copper and steel, makes them compatible with different pipeline systems and equipment within the sector.

Furthermore, advancements in soldering techniques and material research are continually improving the durability and reliability of solder ring joints. As a result, these joints are likely to become an integral part of future oil and gas infrastructure, ensuring the industry's continued growth and sustainability.

Solder ring joints offer an outstanding solution for secure and reliable connections in the oil and gas industry. With their superior sealing properties, excellent resistance to corrosion, and ability to withstand high pressure, these joints provide a dependable and durable connection method for oil and gas pipelines, storage tanks, and other critical equipment. As the industry continues to prioritize safety and efficiency, solder ring joints are set to play a crucial role, helping drive the sector forward towards a more secure and reliable future.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文