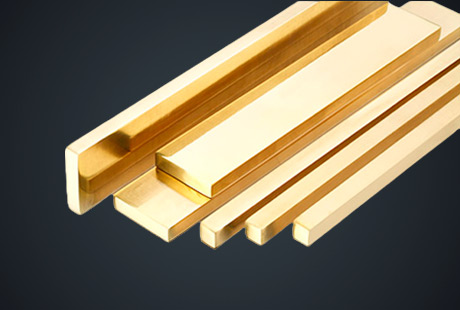

Copper alloys are known for their exceptional properties and versatility, and Chromium Zirconium Copper is no exception. This unique alloy combines copper with chromium and zirconium, resulting in a material with distinct characteristics that make it suitable for a wide range of applications. In this blog post, we will delve into the properties of Chromium Zirconium Copper and explore its various applications in different industries.

High Conductivity and Thermal Stability

Chromium Zirconium Copper exhibits excellent electrical conductivity, making it an ideal choice for applications where efficient electrical conduction is critical. The alloy's high thermal stability ensures that it can withstand elevated temperatures without significant loss of mechanical properties, making it suitable for applications involving heat transfer and thermal management.

Exceptional Strength and Wear Resistance

Compared to pure copper, Chromium Zirconium Copper offers enhanced strength and wear resistance. The addition of chromium and zirconium improves the alloy's hardness and mechanical properties, making it suitable for applications subjected to mechanical stress, friction, or wear. It exhibits better durability and longevity, ensuring reliable performance in demanding environments.

Corrosion Resistance

Chromium Zirconium Copper demonstrates good resistance to corrosion, enabling its use in applications exposed to moisture or corrosive substances. While not as corrosion-resistant as some specialized copper alloys, Chromium Zirconium Copper still offers a favorable balance between corrosion resistance and other desirable properties, making it a versatile choice for various industries.

Compatibility with Joining and Machining Techniques

Chromium Zirconium Copper is compatible with various joining techniques, such as brazing and soldering, allowing for ease of assembly in manufacturing processes. Additionally, it exhibits good machinability, enabling precise shaping and machining to meet specific application requirements. This versatility in joining and machining techniques contributes to its widespread use in different industries.

Diverse Applications

The unique properties of Chromium Zirconium Copper make it suitable for a wide range of applications across industries. It finds use in electrical connectors, terminals, and conductive components in electrical engineering. The alloy's strength and wear resistance make it ideal for manufacturing tooling, molds, and dies. It also finds applications in aerospace components, heat exchangers, and renewable energy systems, where its combination of properties contributes to performance and reliability.

Chromium Zirconium Copper is a versatile copper alloy with distinct properties that set it apart from other materials. Its high conductivity, thermal stability, strength, wear resistance, and corrosion resistance make it suitable for a diverse range of applications across industries. From electrical engineering and manufacturing to aerospace and thermal management, this alloy contributes to the success of various systems and technologies. By understanding the unique properties of Chromium Zirconium Copper, engineers and manufacturers can make informed decisions when selecting materials for their specific applications, ensuring optimal performance and longevity.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文