Contamination in refrigeration systems can lead to performance issues, system failures, and compromised product quality. Copper fittings play a vital role in preventing contamination and maintaining the integrity of refrigeration systems. In this blog post, we will explore the significant role of copper fittings in preventing contamination and preserving the purity of refrigeration systems. We will delve into the reasons why copper fittings are crucial in this regard and how they contribute to the overall performance and reliability of refrigeration systems.

Non-Reactive and Non-Porous Material

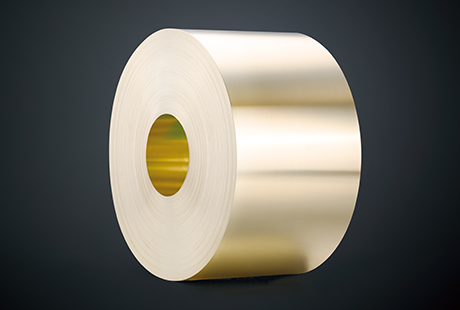

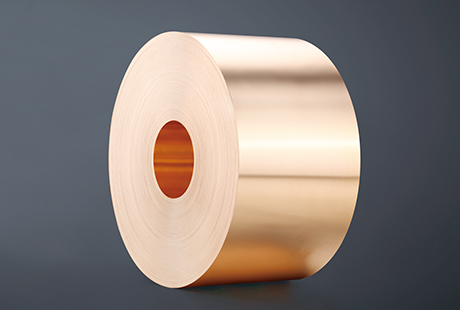

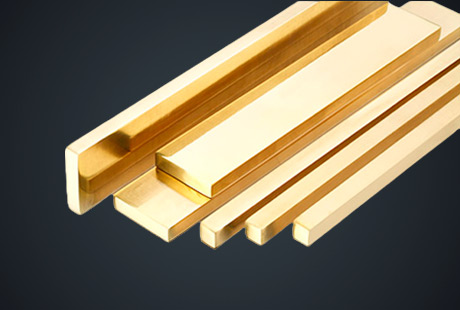

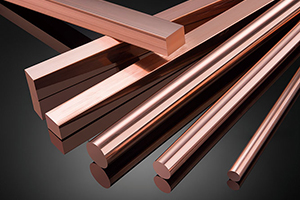

Copper is a non-reactive and non-porous material, making it an excellent choice for preventing contamination in refrigeration systems. Unlike some other materials, copper does not react with or contaminate the refrigerant or other substances within the system. This non-reactive property ensures that the refrigerant remains pure and free from any unwanted reactions or contaminants that could compromise system performance or product quality.

Antibacterial and Antimicrobial Properties

Copper has inherent antibacterial and antimicrobial properties, known as the "antimicrobial effect." These properties help inhibit the growth of bacteria, viruses, and other microorganisms on the surface of copper fittings. By preventing the growth and spread of harmful microbes, copper fittings contribute to the overall cleanliness and hygiene of the refrigeration system, reducing the risk of contamination and potential health hazards.

Easy to Clean and Maintain

Maintaining cleanliness and hygiene is essential in refrigeration systems. Copper fittings are easy to clean and maintain, further preventing contamination. The smooth and non-porous surface of copper fittings resists the accumulation of dirt, debris, and microbial growth. Regular cleaning and maintenance of copper fittings help ensure that the refrigeration system remains free from contaminants, optimizing its performance and preserving the quality of stored products.

Corrosion Resistance and Leak Prevention

Contamination in refrigeration systems can result from leaks caused by corrosion or degradation of fittings. Copper fittings offer excellent corrosion resistance, reducing the risk of leaks and subsequent contamination. Their durable and long-lasting nature helps maintain the integrity of the system, preventing the ingress of contaminants from the environment and preserving the quality of refrigerants and products being stored.

Compliance with Regulatory Standards

Copper fittings meet or exceed regulatory standards for material safety and compatibility with refrigerants. Manufacturers and installers can have confidence in the use of copper fittings in refrigeration systems, knowing that they comply with industry guidelines and requirements. This compliance ensures that the refrigeration system remains free from contamination and operates within the defined safety and performance parameters.

Copper fittings play a crucial role in preventing contamination and preserving the purity of refrigeration systems. Their non-reactive nature, antibacterial properties, ease of cleaning and maintenance, corrosion resistance, and compliance with regulatory standards make copper fittings indispensable in ensuring clean and reliable refrigeration systems. By choosing copper fittings, professionals in the field can effectively prevent contamination, maintain product quality, and enhance the overall performance and longevity of refrigeration systems. Embrace the role of copper fittings in contamination prevention and experience the benefits they bring to the cleanliness and efficiency of your refrigeration systems.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文