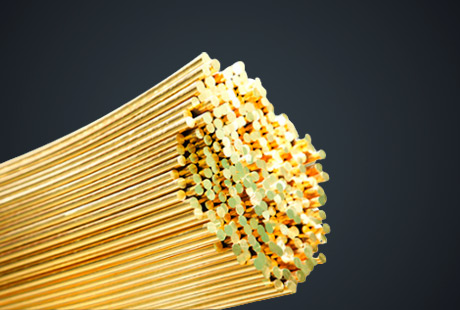

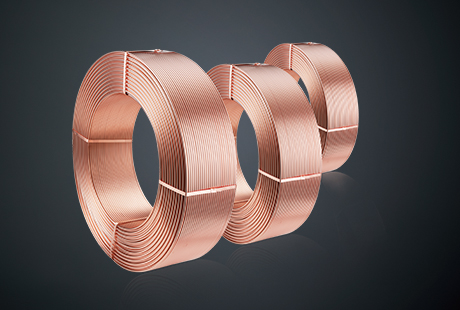

Aerospace engineering demands the utmost precision, reliability, and safety in every component used. Enamel coated wire, also known as magnet wire, is a critical element that fulfills these requirements in the aerospace industry. From aircraft systems to space exploration, enamel coated wire plays a vital role in ensuring efficient electrical performance and reliability. In this blog, we will explore the key role of enamel coated wire in aerospace engineering and its applications in this high-stakes industry.

Electrical Systems in Aircraft

Aircraft electrical systems are essential for communication, navigation, avionics, and control. Enamel coated wire, with its excellent electrical insulation and thermal conductivity, is widely used in aircraft electrical systems. It ensures reliable performance even in demanding flight conditions, where temperature fluctuations, vibrations, and electrical interference are common. The lightweight design of enamel coated wire is particularly advantageous in aerospace applications, contributing to overall fuel efficiency.

Actuators and Control Systems

Enamel coated wire is a crucial component in actuators and control systems, responsible for the movement and precision control of various aircraft parts, such as flaps, rudders, and ailerons. These critical systems require wires with high mechanical strength, thermal stability, and consistent electrical performance. Enamel coated wire meets these criteria, ensuring smooth and reliable operation of actuators and control systems in aerospace engineering.

Aerospace Sensors and Avionics

In aerospace sensors and avionics, where accurate and reliable data is essential for flight operations and safety, enamel coated wire plays a vital role. It is used in various sensors, such as pressure sensors, temperature sensors, and magnetic sensors, to ensure precise signal transmission and data acquisition. Additionally, enamel coated wire is integral to avionics systems, contributing to efficient signal processing and communication within the aircraft.

Space Exploration and Satellite Technology

In space exploration missions and satellite technology, where the components must withstand extreme conditions and operate flawlessly over extended periods, enamel coated wire is a preferred choice. Its ability to maintain reliable electrical performance in the vacuum of space, exposure to radiation, and temperature variations makes it indispensable for space applications. Enamel coated wire is used in satellite communications, solar panel deployment mechanisms, propulsion systems, and various other space-related technologies.

Weight and Space Efficiency

A key advantage of enamel coated wire in aerospace engineering is its weight and space efficiency. With the need to minimize weight in aircraft and spacecraft, enamel coated wire's lightweight design helps reduce overall system mass. Additionally, its compact size allows for space-efficient designs, making it valuable in applications where space is limited, such as in satellites and small spacecraft.

As aerospace technology continues to advance, enamel coated wire remains at the forefront of innovation, meeting the stringent demands of the industry and enabling the exploration of new frontiers in aviation and space exploration. Its vital role in aerospace engineering underscores its significance as a high-performance component in one of the most critical and dynamic industries in the world.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文