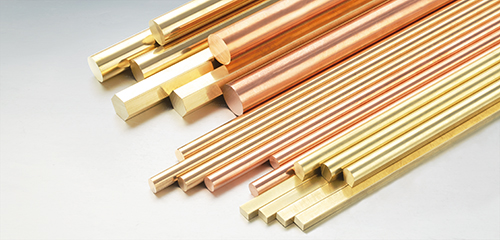

Copper tubes can be classified into three main categories: phosphorus deoxidized copper tubes, purple copper tubes, and oxygen-free copper tubes. Let's briefly introduce each of them.

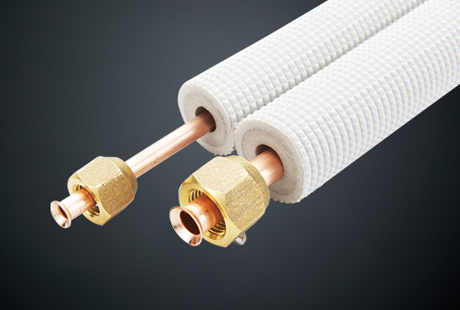

TP2 (Phosphorus Deoxidized Copper)

TP2 is phosphorus deoxidized copper, with a copper content according to national standards of 99.90%. Approximately 0.015% of phosphorus is added during the smelting process to improve the welding performance of copper tubes. It is mainly used in products with frequent air conditioning welding to avoid "hydrogen embrittlement" and is easier to weld than T2.

Due to the addition of phosphorus elements in TP2 material, it exhibits relatively greater ductility. TP2 is widely used in the manufacturing of air conditioning refrigerant connection pipes, gas circuit connection pipes for stoves, electric heating pipes, etc.

T2 (Pure Copper)

T2 is pure copper with a copper content higher than 99.90%. When users require high conductivity from the material, T2 copper tubes are the preferred choice.

TU1 (Oxygen-Free Copper)

TU1 is oxygen-free copper, essentially higher purity copper with a copper content ≥99.97%. It has extremely low oxygen and impurity content, with phosphorus content lower than 0.002%. TU1 exhibits excellent electrical and thermal conductivity, good ductility, and superior processing, welding, corrosion resistance, and cold resistance. The uniformity of TU1's internal crystal grains and the significant reduction of secondary phase particles at grain boundaries result in enhanced ductility. This increased ductility leads to better processing consistency. TU1's strain distribution uniformity in the processing of trumpet mouths is significantly advantageous compared to TP2. This means that if TU1 is used for making connection pipes, the processing of the trumpet mouth will be more stable and reliable, ensuring a stable sealing characteristic of the connection pipe. Due to its high production requirements and costs, TU1 copper tubes are priced much higher than other categories of purple copper tubes.

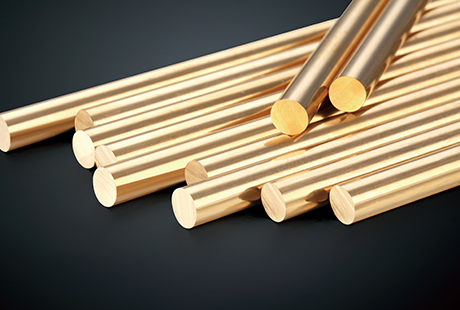

Generally, processed copper tubes are divided into three types: hard, semi-hard, and soft. Their flexibility varies, and their quality can be assessed by bending the copper tube. A high-quality copper tube is easy to bend, but if it is difficult to bend or exhibits cracking after bending, it indicates lower quality.

T2, TP2, TU1 copper tubes that produced in Jintian Copper, demonstrates excellent thermal and electrical conductivity. Utilizing advanced production processes and equipment ensures precise dimensions and a smooth surface, allowing effective fluid and gas transport. These copper tubes find extensive applications in refrigeration, industrial, construction, and residential sectors. Additionally, Jintian Copper's copper tubes exhibit corrosion resistance and high-temperature durability, making them suitable for prolonged operation in harsh environmental conditions. Whether used in heating systems, air conditioning systems, or the manufacturing of automotive components, Jintian Copper's copper tubes meet customer requirements, providing reliable performance and durability. Feel free to inquire at 0574-83005999.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文