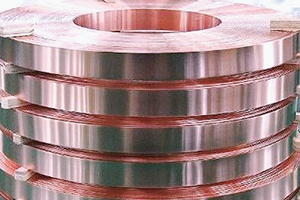

Copper foil holds immense importance in various industries due to its excellent electrical conductivity, thermal properties, and corrosion resistance. However, when it comes to selecting the right copper foil, there are numerous options to consider. One form that stands out is rolled annealed copper foil, which offers several advantages and benefits over other copper foils. In this article, we will explore the unique features of Jintian Copper's rolled annealed copper foil and examine why it is the superior choice in various applications.

Superior Conductivity:

One of the most significant advantages of rolled annealed copper foil is its exceptional electrical conductivity. The foils of Jintian Copper are meticulously manufactured to achieve a high degree of purity, resulting in low electrical resistance. This remarkable conductivity ensures minimal power loss and enhanced signal transmission in demanding electrical applications. Whether it is for printed circuit boards (PCBs), batteries, or electromagnetic shielding, rolled annealed copper foil ensures optimal performance.

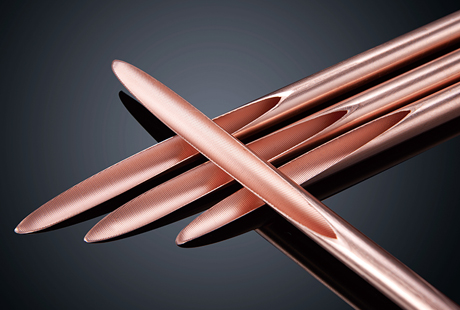

Enhanced Flexibility:

Rolled annealed copper foil offers superior flexibility compared to other copper foils. This remarkable characteristic stems from the unique manufacturing process employed by Jintian Copper. Through precise control of the annealing process, the foil becomes more malleable without compromising its electrical conductivity. The increased flexibility makes it easier to shape, bend, and mold, thus enabling seamless integration in intricate designs and small spaces, such as in electronic devices and flexible circuits.

Uniform Thickness:

Jintian Copper's rolled annealed foil boasts a remarkable uniform thickness, which significantly contributes to its superior performance. The foil is carefully produced to ensure consistent thickness throughout its entire surface. This precision guarantees an even distribution of electrical and thermal conductivity, avoiding discrepancies that may compromise functionality. The uniform thickness is particularly critical in high-frequency circuits, where any irregularity can cause signal interference or loss of energy.

Excellent Surface Quality:

The surface quality of copper foil plays a crucial role in numerous applications. Rolled annealed copper foil from Jintian Copper boasts an exceptionally smooth and defect-free surface, thanks to stringent quality control measures. The absence of surface imperfections helps to minimize the risk of electrical shorts and ensures reliable and sustainable performance. Furthermore, the smooth surface promotes superior adhesion properties, enhancing the foil's suitability for applications that require lamination or bonding.

When it comes to copper foils, Jintian Copper's rolled annealed copper foil stands out as the premium choice. Its superior conductivity, enhanced flexibility, uniform thickness, and excellent surface quality elevate it above other copper foils in the market. Whether you are in the PCB manufacturing, battery production, or electronic industry, choosing rolled annealed copper foil ensures optimal performance and reliability. As technology continues to advance, the demand for high-quality copper foils will only grow, making Jintian Copper's rolled annealed copper foil the go-to solution for the industry's evolving needs.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文