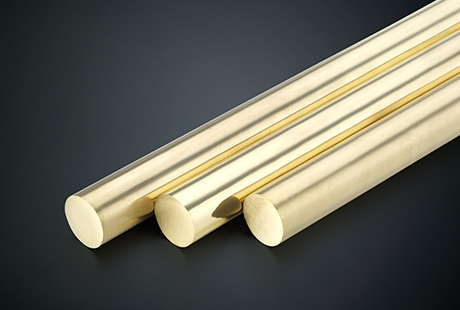

Aluminum bronze bar is an alloy material based on copper, with added aluminum and other alloy elements. The chemical composition of aluminum bronze is usually copper (Cu) 88-92%, aluminum (Al) 8-15%, and impurity elements such as iron (Fe), manganese (Mn), and nickel (Ni). Common national standard grades include QAl9-4, CuAl11Ni6Fe6, CuAl10Ni5Fe4, etc.

High strength, wear-resistant, and corrosion-resistant aluminum bronze alloy:

Similar grades | Chemical composition |

USA UNS | C63000 | Cu | Balance |

EU EN | CW307G/CuAI10Ni5Fe4 | Al | 8.5-11 |

China GB | QAI10-4-4 | Ni | 4.0-6.0 |

UK BS | CA104 | Fe | 3.0-5.0 |

USA UNS | C62300 | Cu | Balance |

EU EN | CuAI10Fe3 | Al | 8.0-11 |

China GB | QAI9-4 | Fe | 2.0-4.0 |

Aluminum bronze can be heat-treated to increase its strength. It has higher strength than tin bronze and good resistance to high-temperature oxidation. Aluminum bronze with iron and manganese elements has higher strength and wear resistance. It can improve hardness after quenching and tempering, and has good high-temperature corrosion resistance and oxidation resistance.

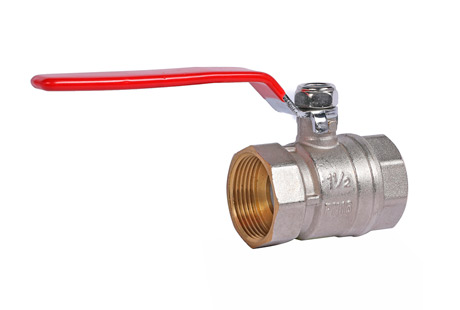

It has good corrosion resistance in atmospheric, fresh water, and sea water. It has moderate machinability, is not easily brazed, and has good hot workability under hot state. Aluminum bronze bars are widely used in the engineering machinery industry, such as high-speed railway contact wire clips, bearings, bushings, pump valve bodies, valve stems, and pivot shafts.

The Advantages of Aluminum Bronze Bars

High Strength

Aluminum bronze bars have high strength and hardness, capable of bearing high loads and strong forces.

Good Corrosion Resistance

Aluminum bronze bars have good corrosion resistance, able to resist the erosion of acids, alkalis, and other chemical substances.

Good Thermal Conductivity

Aluminum bronze bars have good thermal conductivity, allowing for rapid heat conduction and dissipation. They are suitable for applications with high thermal conduction requirements.

Good Ductility

Aluminum bronze bars have good ductility and can change their shape and size through extrusion, stretching, and other processing methods to meet different engineering requirements.

Non-magnetic

Aluminum bronze bars have low magnetic permeability and are not easily affected by magnetic fields.

The Disadvantages of Aluminum Bronze Bars

High Cost

Compared to ordinary copper materials, aluminum bronze has a higher cost, which increases manufacturing costs.

Large Coefficient of Thermal Expansion

Aluminum bronze has a large coefficient of thermal expansion, which may cause dimensional changes during thermal expansion and contraction. The effects of thermal expansion and contraction on parts need to be considered.

High Hardness

Although high hardness is an advantage of aluminum bronze, it also increases the difficulty of machining, requiring the use of higher-level cutting tools.

Heavy Weight

Due to the high density of aluminum bronze materials, aluminum bronze bars of the same volume will appear heavier compared to other materials.

Jintian Copper is a professional manufacturer of aluminum bronze bars. In the production process, we use the highest quality raw materials and strictly control the proportion of aluminum bronze bars to ensure the stability and reliability of their quality.

The aluminum bronze bars produced by Jintian Copper have high strength, hardness, and rigidity, capable of withstanding high loads and strong forces. At the same time, they have excellent corrosion resistance and are very suitable for harsh working environments.

Jintian Copper is committed to providing high-quality products and satisfactory services. We can customize aluminum bronze bars of different specifications according to customer requirements. Please feel free to contact us at 0574-83005999.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文