What is the purpose of a ball valve?

The ball valve plays a key role in the pipeline system, specifically designed to achieve the cut-off, distribution, and flow direction adjustment of medium. Its uniqueness lies in the fact that it requires only a 90-degree rotational operation and very small torque to achieve a tight closure, greatly enhancing the convenience of operation. The valve core of the ball valve is a sphere that opens or closes the fluid passage by rotating. When the valve core rotates to the closed position, the hole of the sphere aligns with the pipeline, achieving closure; when the valve core rotates to the open position, the hole of the sphere aligns with the pipeline, achieving flow. As the preferred choice for switch and shut-off valves, JINTIAN's 2.5-inch brass ball valve has demonstrated excellent performance advantages in many industrial scenarios. This ball valve, thanks to its special material, not only exhibits excellent corrosion resistance, effectively resisting erosion by various media, but also has outstanding impact resistance, ensuring stability and durability in high-intensity usage environments, thereby extending overall service life and becoming an indispensable important component in the industrial field.

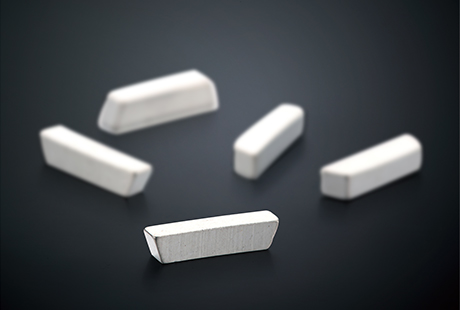

Advantages of JINTIAN 2.5-inch Brass Ball Valve

Ball valve has a simple compact structure, reliable sealing, and convenient maintenance. The sealing surface and the sphere are often in a closed state, making them less likely to be eroded by the medium, easy to operate and maintain. It is suitable for general working mediums such as water, solvent, acid, and natural gas, mainly used for cutting off or connecting the medium in the pipeline and can also be used for fluid regulation and control.

The stem friction torque is small, enabling long-term stable and flexible operation of the stem.

Due to the self-lubricating properties of materials such as PTFE, the friction loss with the sphere is minimal, thus extending its service life.

Low fluid resistance: The ball valve has the lowest fluid resistance among all valve types.

Reliable stem sealing: Since the stem only rotates without lifting movement, the packing seal of the stem is less likely to be damaged, and the sealing ability increases with the pressure of the medium.

Good seat sealing performance: The sealing ring made of elastic materials such as PTFE ensures easy sealing and the sealing ability of the pneumatic ball valve increases with the pressure of the medium.

Simple structure, small size, lightweight.

Convenient operation, rapid opening and closing, requiring only a 90° rotation from fully open to fully closed, making it easy for remote control.

Easy maintenance, the ball valve has a simple structure, and sealing rings are generally movable, making disassembly and replacement convenient.

When fully open or fully closed, the sealing surfaces of the ball and seat are isolated from the medium, preventing erosion of the valve's sealing surfaces as the medium passes through.

Wide applicability, with diameters ranging from a few millimeters to several meters, and can be applied from high vacuum to high pressure.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文