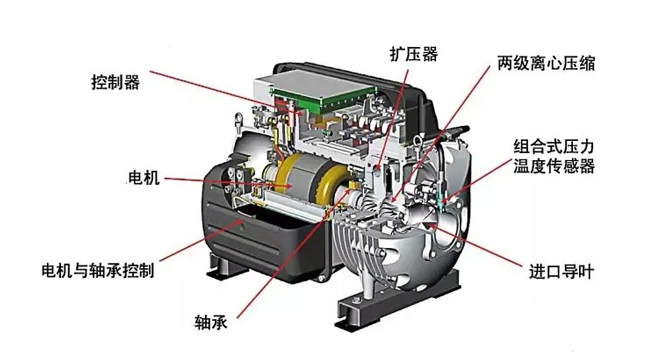

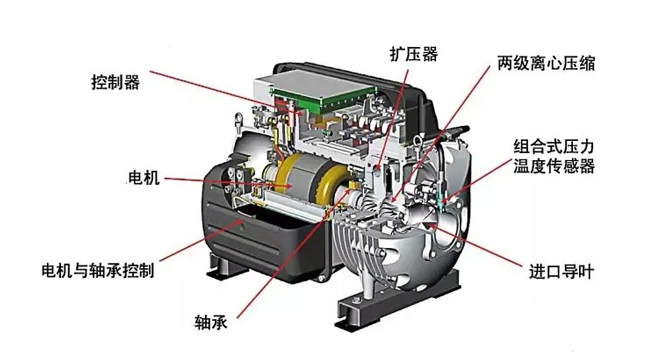

Cooling compressors have many types and forms, which can be divided into displacement and speed types according to their principles, among which the displacement type is the most common.

The basic principle of a refrigeration compressor is to compress the refrigerant into a high-pressure saturated gas (ammonia or fluorine refrigerant), and then condense it through the condenser. After throttling, it is introduced into the evaporator to cool the medium that needs to be cooled. For example, connecting the evaporator to various rooms in a building, the serpentine tube in the evaporator exchanges heat with the air, and then blows the cold air into the room through the blower. The refrigerant in the serpentine tube of the evaporator becomes low pressure vapor and returns to the compressor, where it is compressed and recycled to complete the refrigeration system. The heating system is roughly the same principle, but in reverse.

The Two Displacement Type Compressor: Reciprocating Piston Type and Rotary Type

Reciprocating piston type compressors change the working volume of the gas by the piston's reciprocating motion in the cylinder. Reciprocating piston compressors have a long history and mature production technology.

Rotary compressors include scroll compressors and screw compressors. Most domestic air conditioners use rotary compressors. Screw compressors are mainly used for large refrigeration equipment.

How does a compressor compress gas? Simply put, it completes the process of compressing and conveying gas by changing the volume of the gas! Any power equipment needs a prime mover to perform work. The compressor is the same. It is driven by an electric motor (motor).

The Mainly Two Type of Compressors: Air Conditioning Compressors and Refrigerator Compressors

Air conditioning compressors play a role in compressing and driving refrigerants in the refrigerant circuit of air conditioners. Air conditioning compressors are generally installed in outdoor units. Air conditioning compressors extract refrigerants from the low-pressure zone and compress them to the high-pressure zone for cooling and condensing. Through the radiator fins, heat is dissipated into the air, and the refrigerant changes from a gas to a liquid, with an increase in pressure.

Refrigerator compressors are the power source of refrigerators and can be considered as the heart of refrigerators. They compress refrigerants, improve the pressure and temperature of refrigerants, and promote the circulation of refrigerants in the system. Currently, domestic compressors for household refrigerators and air conditioners are displacement types, which can be divided into reciprocating and rotary types. Reciprocating compressors use piston, crank, and connecting rod mechanisms or piston, crank, and slider mechanisms.

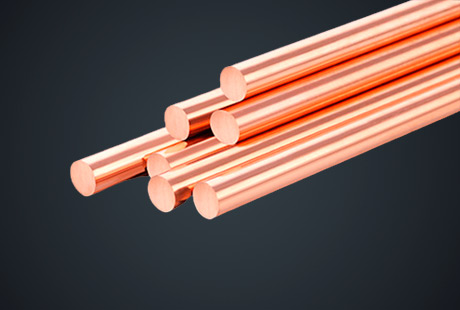

Electromagnetic wire is an important component of compressors, and the performance of electromagnetic wire directly affects the quality and service life of compressors. So, what should we pay attention to? Because the temperature of the compressor will increase during use, the enameled wire is required to have high temperature resistance, high resistance to refrigerants, and resistance to corona discharge. Generally, the initial service life experiment needs to be conducted for half a year; and the surface needs to be coated with refrigeration oil. At present, the main enameled copper wire used in compressors is the Q (ZY+XY)-2/200 model, with a specification of generally 0.40-1.50mm; PT270 wire reels are generally used for product packaging.

Ningbo Jintian Copper (Group) Co., Ltd., founded in 1986, is a large-scale and well-known copper processing enterprise in China. After 25 years of accumulation and sedimentation, the company has become a domestic advanced enameled wire production base, focusing on the research and production of high-precision electromagnetic wire series products. It has won honors such as "Zhejiang Province Quality Trustworthy Product" and "Top Ten Famous Brand of China Enameled Wire".

What Should I Do if the Compressor Does Not Start?

Internal malfunction of the compressor

If after testing, it is found that the accessories of the compressor are fine, but the compressor still cannot start, it may be due to internal rotor seizing and cylinder jamming, requiring replacement of a new compressor.

Short circuit of compressor winding

This can be tested with a multimeter. Usually, a zero or infinite resistance value indicates a problem, which needs to be repaired or replaced with a new compressor.

Inter-turn short circuit of compressor motor

In this case, the compressor usually cannot start. It needs to be replaced with a new compressor to eliminate the fault.

Temperature controller failure

It is not the fault of the compressor that causes the compressor not to start. If the temperature controller fails, it can also cause this situation. Normally, the temperature controller needs to be repaired to eliminate the fault.

How to Replace the Compressor?

● Cut off the power supply of the refrigerator and safely open the back of the refrigerator with a screwdriver.

● Separate the process pipe of the refrigerator compressor and release the refrigerant. The tool used is a mini cutting knife, be careful not to use the wrong one.

● After all the refrigerant is released, cut open the low-pressure and high-pressure pipes, because they are connected to the compressor and cannot be removed without separating them.

● Open the junction box of the compressor, unplug the power cord connected to it, and then remove the bottom foot clip, remember to remove all of them.

● Take out the compressor, sand the cut pipe end with sandpaper, put the new compressor in, fix it properly, install the clip, tighten it with screws, and then insert the power cord. Grind the high-pressure pipe and low-pressure pipe with a chamfering tool.

● After the compressor has been replaced, add refrigerant, put the back cover of the refrigerator back on, and test it with electricity.

Jintian electromagnetic wire products include corona-resistant enameled copper round (flat) wire, polyester imide/polyamide-imide composite enameled copper round (flat) wire, and directly weldable polyurethane enameled copper round wire, which comply with the EU ROHS directive requirements. The main products have passed UL safety certification and are widely used in automotive industry, motors, transformers, compressors, as well as new energy vehicles, rail transit, wind power, and other fields, and are exported to more than 30 countries and regions such as Japan, Europe, and the Americas.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文