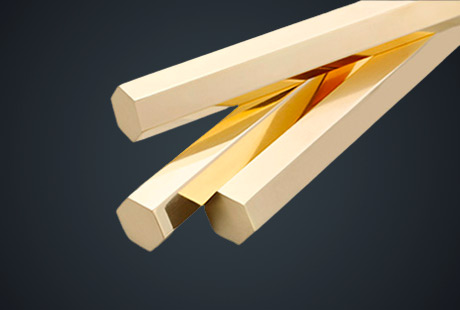

Enamel insulated wire is a main variety of winding wire. It consists of conductor and insulating layer. After the bare wire is softened by annealing, it is painted and baked many times.

However, it is not easy to produce products that meet both standard requirements and customer requirements. It is affected by the quality of raw materials, process parameters, production equipment, environment and other factors. Therefore, the quality characteristics of various enamel insulated wires are different, but all have mechanical properties, chemical properties, electrical properties, thermal properties.

Ⅰ. Appearance inspection of enamel insulated wire

The surface is smooth, uniform in color, free of paint lumps and white lubricants.

Ⅱ. The size inspection of enamel insulated wire

| Product | Level | Size |

| IEC 60317 Enameled Wire | 130(B)、155(F)、180(H) | 0.04-1.8mm |

| JIS 3202 Enameled Wire | 130(B)、155(F)、180(H) | 0.04-1.8mm |

| Magnet Wire for Motor | 130(B)、155(F) | 0.06-4mm |

| Magnet Wire for EV | 180(H) | 0.045-4mm |

| Magnet Wire for Compressor | 200(C)、220(C) | 0.08-4.0mm |

| Anti-Corona Magnet Wire | 200(C) | 0.3-2.0mm |

| Plate Magnet Wire | 130(B) | 1.5mm²-50mm² |

| 155(F) |

| 180(H) |

| 200/220(C) |

240(C)

|

1. Diameter of enamel insulated wire: standard reference GB/T6109, inspection method: micrometer;

2. Conductor diameter: standard reference GB/T6109, inspection method: micrometer;

3. Diameter of enamel insulated wire: standard reference GB/T6109, inspection method: micrometer;

4. Conductor error value: standard reference GB/T6109.

Ⅲ. Mechanical properties of enamel insulated wire

1. Elongation: the standard refers to GB/T6109, inspection method: stretching instrument;

Calculation method: ratio of (length after stretching - length before stretching) / length before stretching;

2. Sudden pull break: The standard is to pull at a speed of 2 meters per second to check that the paint film is not cracked;

3. Round rod winding: winding the enamel insulated wires of different specifications and the corresponding copper rods ten times to check that the paint film has no cracks, and the diameter of the copper rods refers to the requirements of GB/T6109;

4. Thermal shock: Put the coiled enamel insulated wire, like enamel coated copper wire, in an oven (hang in the middle of the oven) for 0.5 hours. The oven temperature corresponds to the specifications of the enamel insulated wire, refer to G/T6109, and check that the paint film is free of cracks after drying.

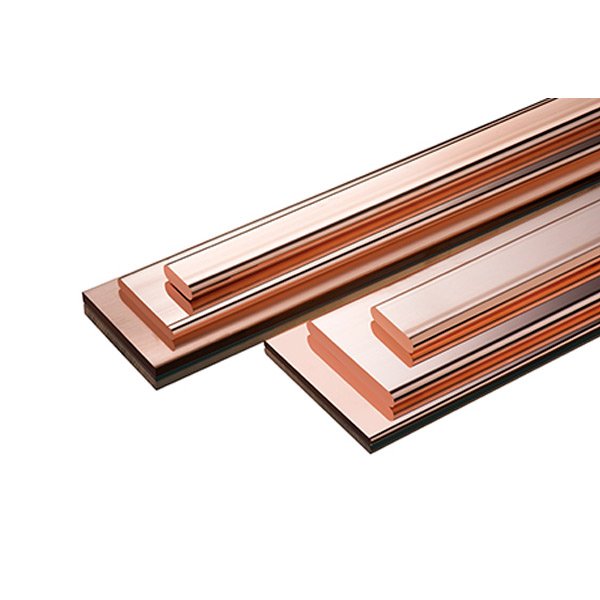

Ⅳ. The electrical properties of enamel insulated wire

1. Resistance:

Take 1m of the enamel insulated wire to be tested, scrape off the paint film at both ends, and measure the resistance of the enamel insulated wire. Like flat enameled copper wire, the resistance measurement value should be within the resistance range required by GB/T6109; the standard temperature is 20 degrees, and the conversion formula is: 20 degrees resistance / 234.5 + standard temperature=actual measured resistance/234.5+measured temperature.

2. Breakdown voltage:

Remove the paint film from both ends of the 0.5m sample of enamel insulated wire, fold it in half, and twist it into a pair on a special twisting machine. When twisting, the force applied to the wire pair and the number of twisting turns should refer to the specified requirements. Cut off the top of the twisted part, and make the distance between the ends of the cut part to be the largest (there are two wire ends at each end), and use a high voltage meter to test the high voltage of the two wires at the same end.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文