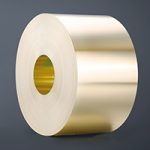

Copper, with its exceptional electrical conductivity and malleability, has been a valuable metal for centuries. One versatile form of copper is the thin copper sheet roll, which finds extensive applications in various industries. In this blog, we will explore the numerous uses and benefits of thin copper sheet rolls, highlighting their indispensable role in various sectors.

Electrical and Electronics Industry

The electrical and electronics industry heavily relies on thin copper sheet rolls for manufacturing a diverse range of products. From printed circuit boards (PCBs) and connectors to transformers and power cables, thin copper sheet rolls serve as a fundamental component. Due to their excellent conductivity, flexibility, and reliability, they facilitate efficient current flow, reducing energy loss and improving overall performance. The malleability of thin copper sheet rolls also allows for intricate designs, enabling miniaturization in electronic devices.

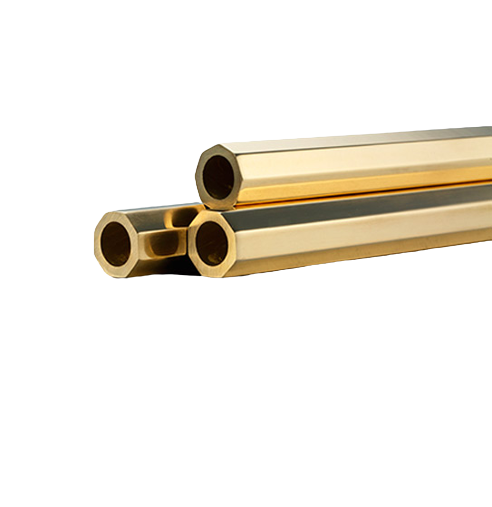

Architecture and Construction

In the architecture and construction sector, thin copper sheet rolls play a vital role in both aesthetics and functionality. The malleability of copper allows it to be easily formed into various shapes, making it ideal for roofing, cladding, and decorative elements. Copper's natural ability to develop a patina over time gives buildings a distinctive and timeless appearance. Additionally, copper's corrosion resistance and durability ensure long-lasting structures, making it a preferred material for plumbing systems and HVAC (Heating, Ventilation, and Air Conditioning) applications.

Automotive and Transportation

Thin copper sheet rolls find significant applications in the automotive and transportation industries. Copper's excellent thermal conductivity and electrical properties make it indispensable for wiring and cabling in automobiles. This enables efficient power transmission and reduces the risk of overheating. In addition, copper's anti-corrosive nature contributes to the longevity and reliability of vehicle components, such as radiators and heat exchangers. The flexibility of thin copper sheet rolls also allows for intricate shaping, making them suitable for various automotive parts.

Renewable Energy

With the growing emphasis on renewable energy sources, thin copper sheet rolls have become essential components in the production of solar panels and wind turbine systems. Copper's high thermal and electrical conductivity, along with its corrosion resistance, make it an ideal choice for these applications. Thin copper sheet rolls are utilized in the wiring, busbars, and conductive layers of solar cells, enabling efficient conversion of sunlight into electricity. Similarly, copper is used in transformers and electric generators of wind turbines, ensuring optimal energy generation and transmission.

From the electrical and electronics industry to architecture, automotive, transportation, and renewable energy, thin copper sheet rolls have proven their versatility and importance in a wide range of applications. Their excellent conductivity, malleability, and durability make them an invaluable material for numerous industries. As technological advancements continue to drive innovation, we can expect even more diverse uses for thin copper sheet rolls in various sectors.

Whether it's improving the efficiency of electronic devices, enhancing the longevity of buildings, enhancing vehicle performance, or contributing to sustainable energy solutions, thin copper sheet rolls are an integral element in the advancement of multiple industries. As we embrace a future driven by technological progress, the demand for thin copper sheet rolls will only continue to grow.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文