Subway systems play a vital role in the transportation infrastructure of busy cities. Efficient power distribution is crucial to keep these systems running smoothly and to ensure the safety of millions of commuters every day. When it comes to powering subway networks, electrical copper busbars emerge as the preferred choice for electrical distribution. In this article, we will explore the numerous benefits of using electrical copper busbars in subway power distribution systems.

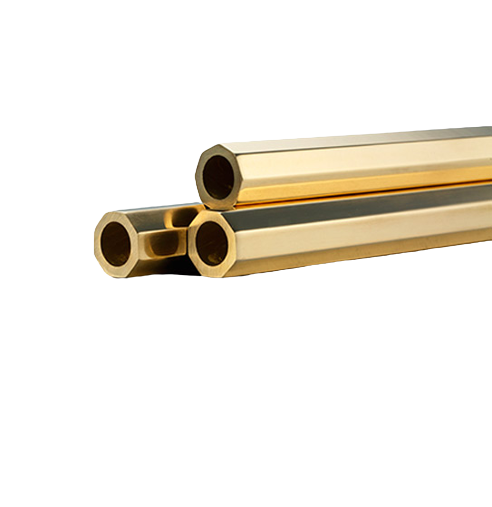

Superior Conductivity

Copper is known for its exceptional electrical conductivity, making it the ideal material for busbars. Subway systems require high power transmission capabilities, and electrical copper busbar efficiently handles the load. The low resistance offered by copper allows for efficient distribution of electricity without excessive energy loss. This results in improved energy efficiency and reduced operational costs for subway networks.

Thermal Performance

Subway systems generate a significant amount of heat due to the power requirements and continuous operation. Copper busbars exhibit excellent thermal conductivity, dissipating heat efficiently and preventing the risk of overheating. This property ensures the longevity of electrical components and reduces the chances of system failure. With electrical copper busbars, subway operators can have peace of mind, knowing that their power distribution system is reliable and can withstand the demanding operating conditions.

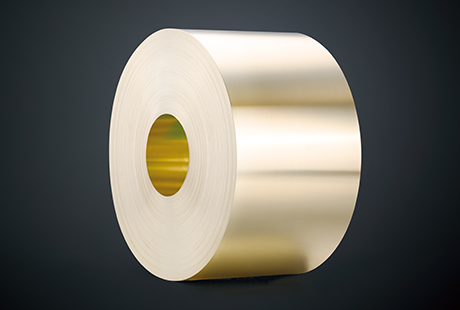

Compact Design

Space constraints are a common challenge in subway power distribution installations. Copper busbars offer a compact design, allowing for efficient use of available space. The high current-carrying capacity of electrical copper busbars means that they can handle more power within a smaller footprint than other materials. By utilizing copper busbars, subway operators can optimize their power distribution installations, saving valuable space that can be utilized for other essential components.

Corrosion Resistance

Subway systems are often exposed to harsh environments, including humidity and chemical contaminants. Copper busbars have excellent corrosion resistance, making them suitable for such demanding conditions. The natural oxidation that occurs on the surface of electrical copper busbars provides a protective layer, preventing further corrosion and ensuring long-term reliability. This resistance to corrosion significantly reduces maintenance requirements, saving time and money for subway operators.

In conclusion, the use of electrical copper busbars in subway power distribution systems offers numerous benefits. The superior conductivity of copper enables efficient electricity transmission, resulting in improved energy efficiency and reduced operating costs. The exceptional thermal performance of copper busbars ensures the longevity of the system, preventing overheating and reducing the risk of failures. Their compact design allows for efficient use of limited space, while their corrosion resistance makes them reliable in challenging subway environments. With these advantages in mind, it is clear why copper busbars are the preferred choice for powering subway networks.

As technology advances, the demand for efficient, reliable, and sustainable power distribution systems will continue to grow. As a copper busbar manufacturer, our copper busbars stand out as a reliable solution that meets these requirements, making them an essential component in subway power distribution. With their exceptional properties, electrical copper busbars are playing a vital role in ensuring the smooth operation of subway systems, contributing to safer and more sustainable urban transportation.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文