Internal thread copper tube, also known as non-smooth tube, refers to TP2 purple copper tube with smooth outer surface and a certain number of internal threads with a certain rule. Due to the increase in the inner surface area of the internal thread copper tube, its thermal conductivity is improved by 20% to 30% compared to the smooth tube.

Currently, the quality requirements for internal thread copper tubes in the refrigeration industry at home and abroad are becoming higher and tending to be smaller and taller.

Smaller specifically refers to small-sized copper tubes.

Taller specifically refers to thin and tall tooth shapes. Generally, when the top angle α of the internal thread tooth is below 40 degrees, the tooth is called thin tooth. Under the condition that the cross-sectional area and the number of threads n are the same, the higher and thinner the thread tooth shape is, the larger the heat exchange area is.

So, what are the common defects to avoid when producing internal thread tubes? The following will be listed one by one:

Insufficient Tooth Height and Unclear Shape

Cause

The outer ring of the rotary pressing ring is too large and the size is not suitable; The wall thickness of the mother tube is too small; The outer diameter of the internal thread core head is too small

Solution

Repair all damaged mold and mother tube sizes Check whether the mold drawings are correct. If the production process is incorrect, change the manufacturing process.

The Surface Spiral Imprint Is Too Deep or Rough, And the Spiral Imprint Is Uneven (Unequal Pitch)

Cause

Severe wear of steel balls or different wear speeds of each ball; Copper chips causing steel balls not to rotate; The outer ring of the rotating pressing ring is too small; The outer ring is too large, resulting in uneven gaps between the ball bodies; Uneven ball sizes.

Solution

Replace the steel balls; Clean the rotary head and replace the entire set of molds.

Breakage Occurs at the Beginning and Middle of the Drawing

Cause

The wall thickness of the mother tube is too thick, resulting in too much pulling force at the moving stretching die. At the same time, after the tube is pulled through the moving stretching die, the lubricating oil film ruptures. In this way, during the subsequent rotary pressing and air drawing processes, the lubricating oil film on the inner wall of the tube may be too thin or absent, resulting in discontinuous drawing; The inner wall of the mother tube is contaminated with oil; There are too many dents or flattening marks on the mother tube, causing the core rod and the inner wall of the tube to stick together; The core rod, moving core head, and internal thread core head cannot rotate due to the bending or too small clearance of the core rod; The ball bodies do not rotate due to incorrect mold. The wall thickness is too small due to excessive reduction in the rotary pressing process; The lubricating oil flow rate is too small and the equipment configuration is incorrect; The outer diameter of the internal thread core head is too large compared to the outer diameter of the moving core head, resulting in the inner thread core head and the inner wall of the tube sticking together and unable to rotate.

Solution

Maintain a reduction of 8~12% at the moving core head to ensure the tolerance range of wall thickness and outer diameter (preferably ±0.02, maximum ±0.03); Before placing the material basket on the uncoiler, check the mother tube, and if there is too much oil contamination on it, slow down the drawing speed or refuse to draw it; Cut off the dented or flattened parts of the mother tube, or slow down the drawing speed when encountering these places;

After polishing the sliding part, check the clearance between the core rod and the moving core head and the inner thread core head; Before purchasing or using the mother tube, be sure to confirm its quality. Pay special attention to confirming that there is no oil contamination on the inner wall of the mother tube, and there are no defects such as dents, cracks, scratches, folds, fractures, and delamination on the coil;

Before use, confirm that the mold rotates well; Replace the rotary pressing ring or internal thread core head; Confirm that the lubrication equipment operates well, the lubricating oil is sufficient and clean; Replace the moving stretching outer die and moving stretching core head.

The Surface Quality Is Too Rough or Uneven

Cause

The grain size of the mother tube is too large (exceeding 0.05mm); There are foreign objects or copper chips in the rotary pressing ring.

Solution

Reduce annealing temperature or increase drawing speed; ◆Use high-pressure air to blow the inside of the rotary pressing ring.

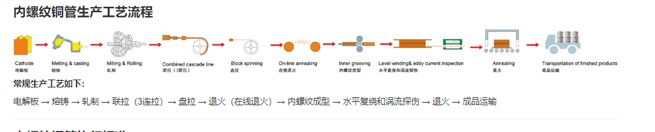

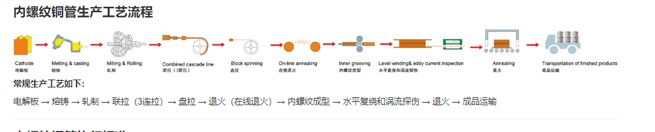

Internal Thread Production Process

Electroplated plate→Melting and casting→Rolling→Drawing (3-Step Drawing)→Coiling→Annealing (Online Annealing)→Internal Thread Forming→Horizontal Rewinding and Eddy Current Testing →Annealing→Finished Product Transportation

Jintian Copper's internal thread copper tube has high dimensional accuracy, high heat dissipation performance, high cleanliness, and lightweight characteristics, and it adapts to the trend of thin-walled, small-diameter, and new tooth-shaped products. Welcome to inquire, contact number: 0574-83005999.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文