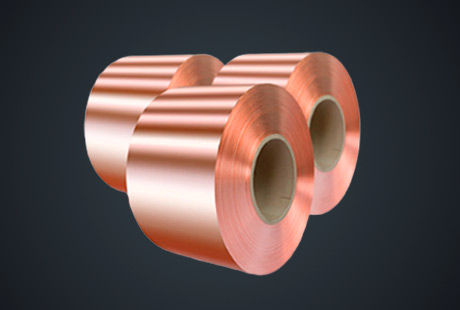

Copper strip connectors are versatile electrical connectors that play a vital role in a wide range of applications. These connectors consist of a flat strip of copper, which is typically tinned or bare, and are used to establish electrical connections between components. In this comprehensive guide, we will delve into the various applications and benefits of copper strip connectors, highlighting their versatility and importance in electrical systems.

Benefits of Using Copper Strip Connectors

Copper strip connectors offer numerous advantages that make them a popular choice in many industries. Firstly, copper is an excellent conductor of electricity, providing low resistance and high conductivity. This enables efficient and reliable electrical connections, minimizing the risk of heat generation or power losses. Additionally, copper is highly resilient to corrosion, making copper strip connectors durable and suitable for long-term use in various environments. Furthermore, copper strip connectors are relatively easy to fabricate and install, allowing for flexibility and customization in different applications.

Industrial Applications of Copper Strip Connectors

Copper strip connectors find extensive use in industrial applications due to their dependable performance and adaptability. They are commonly employed in power distribution systems, ensuring efficient power transmission from transformers to machines or equipment. Copper strip connectors are also utilized in switchgear, circuit breakers, and control panels, facilitating the safe and secure transfer of electrical current. Their ability to withstand high currents and provide reliable connections makes them ideal for heavy-duty applications in industries such as manufacturing, automotive, and renewable energy.

Residential and Commercial Uses of Copper Strip Connectors

In residential and commercial electrical installations, pure copper strip connectors are widely employed to establish connections between electrical wires, switches, outlets, and other devices. They are utilized in electrical panels, allowing for efficient routing and distribution of power throughout a building. Copper strip connectors are also utilized for grounding systems, ensuring safety by providing a low-resistance path for electrical currents to dissipate in the event of a fault or surge. The versatility and durability of these flexible copper strip products make them a dependable choice for both residential and commercial applications.

Customization and Design Considerations

Copper strip connectors offer flexibility in terms of customization and design. They can be fabricated in different shapes, lengths, and thicknesses to suit specific requirements. Various techniques, such as cutting, bending, and punching, can be employed to modify copper strip connectors according to the application's needs. Design considerations, such as the anticipated electrical load, environmental conditions, and mechanical stress, should be taken into account to ensure the connectors perform optimally and maintain their integrity over time.

Maintenance and Inspection

Proper maintenance and periodic inspection of copper strip connectors are essential for ensuring their reliability and safety. Regular visual inspections should be conducted to identify any signs of wear, corrosion, or loose connections. If any issues are detected, prompt action should be taken to rectify the problem, which might include cleaning, tightening, or replacing the connectors. Additionally, routine cleaning and protective measures, such as using appropriate insulating materials, can help prevent corrosion and ensure the longevity of copper strip connectors.

In conclusion, the versatility of copper strip connectors makes them indispensable in various electrical applications. Their efficient conductivity, durability, and flexibility make them an excellent choice for industrial, residential, and commercial projects. By understanding their benefits and considering design considerations, as well as implementing proper maintenance and inspection, these connectors can contribute to reliable and efficient electrical systems.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文