Copper is widely used in the manufacturing of refrigerators due to its excellent thermal conductivity and corrosion resistance. However, the cleanliness of the copper pipes used in refrigerators is a critical factor in ensuring food safety and preventing contamination. High cleanliness copper pipe for refrigerators has emerged as a better choice for food safety, and in this article, we will explore the benefits of using high cleanliness copper pipe in refrigerators.

What is Copper Pipe for Refrigerator?

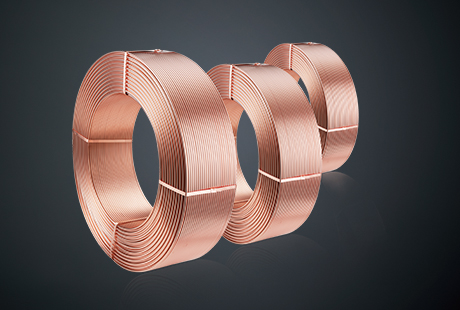

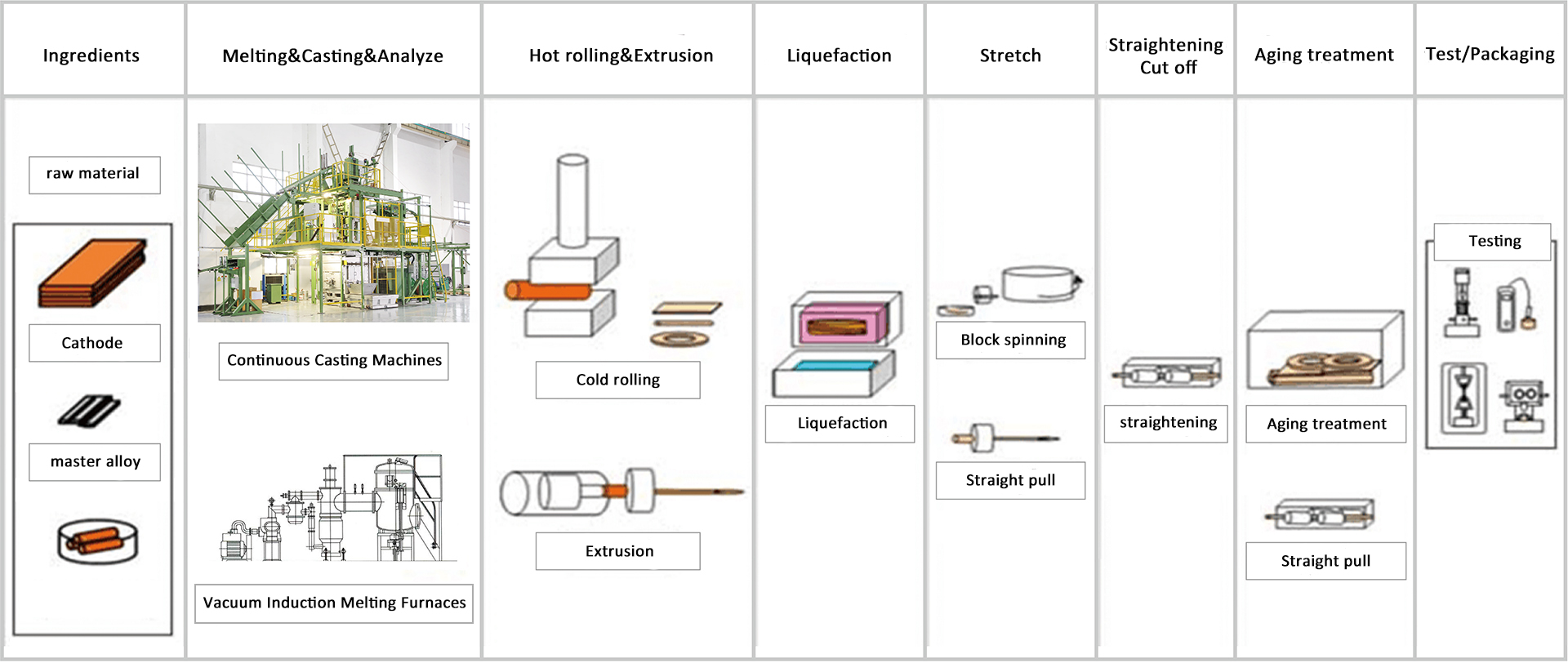

Copper pipe for refrigerator is designed to meet stringent cleanliness standards to ensure food safety. It has a smooth and clean internal surface that is free from contamination, ensuring that the refrigerant fluid and food remain free from impurities and contaminants. High cleanliness copper pipe is manufactured using advanced technologies that eliminate impurities and contaminants, ensuring that the final product is of the highest quality.

Benefits of High Cleanliness Copper Pipe for Refrigerator

Ensures Food Safety: High cleanliness copper pipe for refrigerators plays a crucial role in ensuring food safety. The clean and uncontaminated internal surface of the pipe ensures that the refrigerant fluid and food remain free from impurities and contaminants, preventing the risk of food contamination.

Improves Efficiency: The smooth and clean internal surface of copper pipe for refrigerators improves the overall efficiency of the refrigerator. The smooth surface allows for efficient flow of the refrigerant fluid, reducing the energy consumption of the refrigerator and improving its overall performance.

Increases Durability: High cleanliness copper pipe for refrigerators is highly durable and resistant to corrosion, ensuring that the refrigerator remains reliable and safe for years to come. Unlike traditional copper pipes that can deteriorate over time, copper pipes are designed to last.

Easy to Clean: High cleanliness copper refrigeration pipe fittings is easy to clean due to its smooth and uncontaminated internal surface. Any contaminants can be easily removed from the pipe, ensuring that the pipe remains clean and free from impurities.

Applications of High Cleanliness Copper Pipe for Refrigerator

Copper pipe for refrigerators is used in a variety of applications where food safety is critical. Some of the most common applications of copper pipe for refrigerators include:

Commercial Refrigeration: Copper pipe for refrigerators is widely used in commercial refrigeration applications, including restaurants, grocery stores, and food storage facilities. The clean and uncontaminated internal surface of the pipe ensures that food remains safe and free from contamination.

Residential Refrigeration: Copper pipe for refrigerators is also used in residential refrigeration applications. It is commonly used in refrigerators, freezers, and other appliances where food safety is critical.

Medical Refrigeration: Copper pipe for refrigerators is also used in medical refrigeration applications, including vaccine storage and blood bank refrigerators. The clean and uncontaminated internal surface of the pipe ensures that the medical products remain safe and free from contamination.

Maintenance and Care for Copper Pipe for Refrigerator

High cleanliness copper pipe for refrigerators, like thin brass strips, requires minimal maintenance and care to ensure its longevity and reliability. Regular inspections can help to identify and prevent potential issues before they become major problems.

One of the most important steps in maintaining copper pipe for refrigerators is to ensure that it is kept clean and free from debris. Any debris or buildup on the internal surface of the pipe can interfere with the flow of the refrigerant fluid, reducing the efficiency and performance of the refrigerator.

Additionally, it is important to ensure that the refrigerant fluid is of the highest quality and free from contaminants. Regular testing and analysis can help to identify any potential issues with the refrigerant fluid, ensuring that it remains safe and free.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文