Efficiency and reliability are key factors in any industrial setup. When it comes to electrical wiring, the choice of connectors plays a crucial role in ensuring uninterrupted power supply and reducing the potential for downtime. Among the many options available on the market, copper strip connectors have emerged as a preferred choice for various industrial applications. In this blog post, we will explore how copper strip connectors enhance efficiency in industrial wiring.

Enhanced Conductivity for Seamless

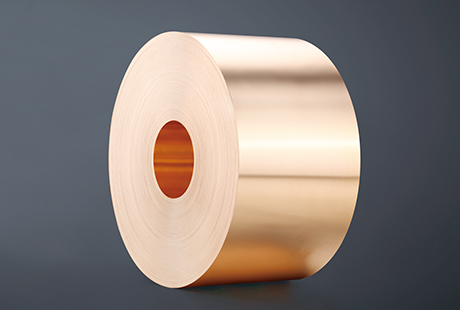

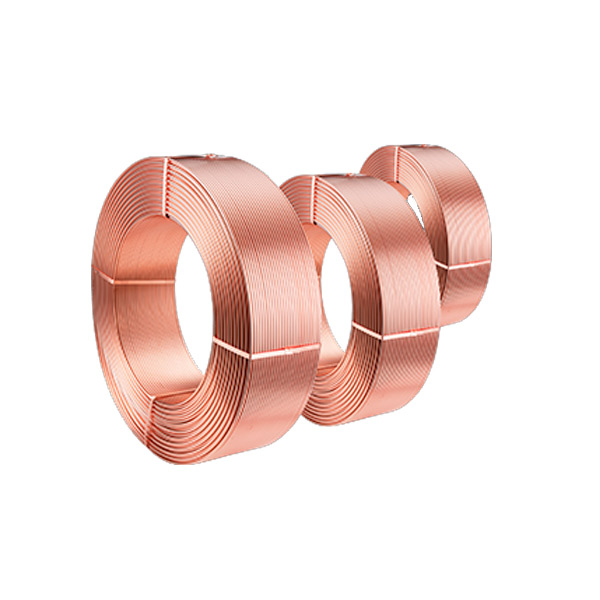

Copper is renowned for its excellent electrical conductivity, making it an ideal choice for power transmission. Copper strip connectors offer a larger surface area for conducting electricity compared to traditional connectors, enabling seamless transfer of power across multiple devices. This enhanced conductivity ensures minimal energy loss, reducing the overall power consumption and enhancing the efficiency of the industrial wiring system.

Flexibility and Easy Installation

Industrial setups often require complex wiring configurations to accommodate a large number of machines and equipment. Copper strip connectors provide the necessary flexibility to accommodate these complex wiring needs. The cooper strips can be easily molded, bent, or cut to fit even the most intricate wiring patterns. This flexibility not only simplifies the installation process but also allows for easy modifications and expansions in the future, thereby streamlining maintenance and reducing downtime.

Superior Heat Dissipation for Enhanced Safety

Efficient heat dissipation is vital to ensure safety in industrial wiring. The high electrical conductivity of copper strip connectors aids in the effective transmission of heat away from critical connections, preventing overheating. The superior heat dissipation properties of copper strips minimize the risk of short circuits, electrical faults, or even electrical fires, thereby ensuring a safer working environment for personnel and reducing costly repairs or replacements.

Durability and Longevity

Industrial environments tend to be harsh, with various factors that could potentially damage electrical connections. Copper strip connectors are known for their durability and corrosion resistance, making them highly suitable for demanding industrial applications. The type of copper strip products is less prone to damage caused by moisture, chemicals, or vibrations, ensuring a longer lifespan and reducing the need for frequent replacements. This inherent durability not only saves time and money but also contributes to the overall efficiency of the industrial wiring by minimizing maintenance requirements.

Copper strip connectors have become an indispensable component of efficient industrial wiring systems. From enhanced conductivity and flexibility to superior heat dissipation and durability, these connectors offer a range of benefits that can significantly improve the efficiency and reliability of electrical installations. By choosing copper strip connectors, industrial setups can enjoy reduced downtime, optimized power transmission, improved safety, and cost savings in the long run.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文