The maritime industry has always been at the forefront of technological innovation. From navigation systems to communication equipment and power distribution, the demands on electrical systems within ships and vessels are constantly evolving. Tinned copper busbars play a crucial role in ensuring the safety and reliability of electrical connections in marine applications. In this article, we'll dive deep into the significance of tinned copper busbars in the marine industry.

Why Tinned Copper Busbars?

Corrosion Resistance

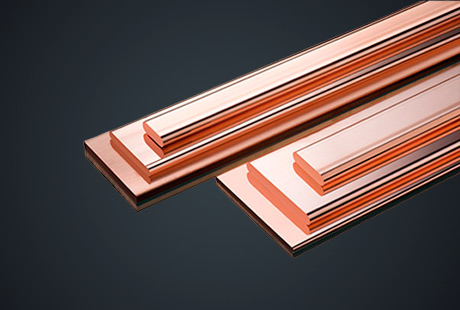

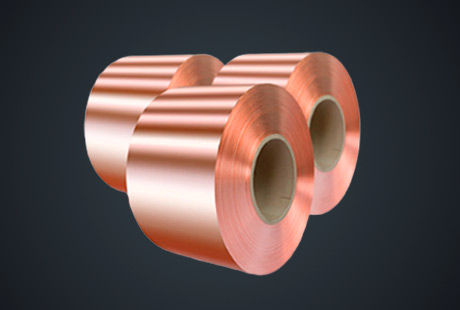

One of the primary challenges in marine environments is the constant exposure to saltwater, which can lead to rapid corrosion of electrical components. Tinned copper busbars are known for their exceptional resistance to corrosion. The tinning process involves coating the copper surface with a thin layer of tin, forming a protective barrier that shields the copper from the corrosive effects of saltwater, humidity, and other environmental factors. This corrosion resistance ensures the longevity and reliability of electrical connections on ships.

Excellent Conductivity

Copper is renowned for its excellent electrical conductivity. When combined with the tinning process, custom copper busbar maintain this high level of conductivity, allowing for efficient power distribution throughout the vessel. This conductivity is critical for the safe and reliable operation of various systems, including lighting, navigation, communication, and propulsion.

High Temperature Tolerance

Marine environments can expose electrical components to extreme temperatures. Tinned copper busbars are designed to withstand these temperature fluctuations without compromising their electrical performance. Their ability to handle high temperatures is essential for avoiding overheating and electrical failures, which can have severe consequences in a marine setting.

Applications in Marine Industry

Tinned copper busbars find application in various systems across different types of vessels:

Power Distribution

Tinned copper busbars are used in power distribution panels to ensure a stable supply of electricity to essential systems on board, such as lighting, HVAC, and communication equipment. The corrosion resistance of tinned copper ensures that power distribution remains reliable even in harsh marine conditions.

Engine Rooms

Marine engines and propulsion systems rely on tinned copper busbars for electrical connections. The high temperature tolerance of tinned copper is crucial in engine rooms, where heat levels can be extreme. This ensures the safe operation of the vessel's propulsion system.

Navigational Equipment

Navigation systems are critical for safe maritime operations. Tinned copper busbars are used to power and interconnect navigation equipment, including GPS, radar, and communication systems. The corrosion-resistant properties of tinned copper are particularly beneficial for ensuring that these systems continue to function accurately.

Tinned copper busbars are the unsung heroes of the maritime industry, playing a vital role in ensuring safe and reliable electrical connections. Their corrosion resistance, excellent conductivity, and high-temperature tolerance make them an ideal choice for the unique challenges presented by marine environments. By using tinned copper busbars, shipowners and operators can have confidence in the electrical systems that power their vessels, ultimately contributing to the safety and efficiency of marine transportation.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文