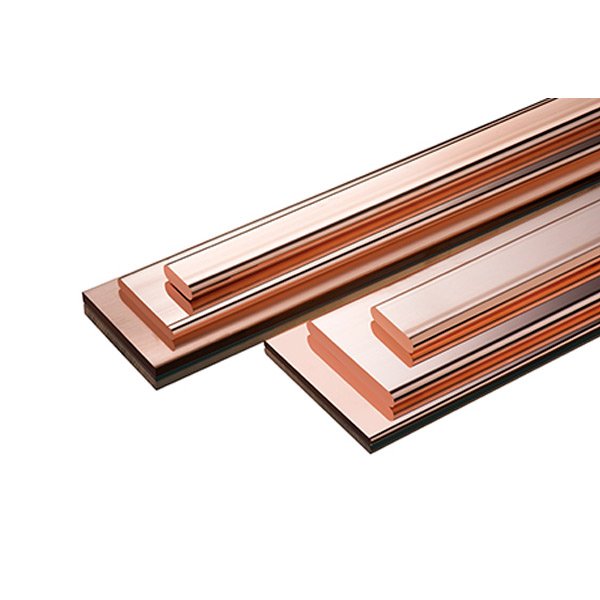

Copper strips can be categorized into various types based on different classifications. According to production methods, they are divided into: electrolytic copper strips and rolled copper strips. This article will focus on explaining what rolled copper strips are.

Applications of Rolled Copper Strips

Rolled copper strips are products formed by repeated rolling and annealing (with thickness typically ranging from 0.15 to 7 millimeters and width usually less than 600 millimeters). They offer superior ductility, bend resistance, and electrical conductivity compared to electrolytic copper foils, and have a higher copper purity.

Jintian Copper's rolled copper strips are primarily used in electronics, electrical equipment, communications, networks, machinery, construction, and home appliances. They are widely sold across domestic provinces and cities and are exported to countries and regions including South Korea, Japan, Hong Kong, and Southeast Asia.

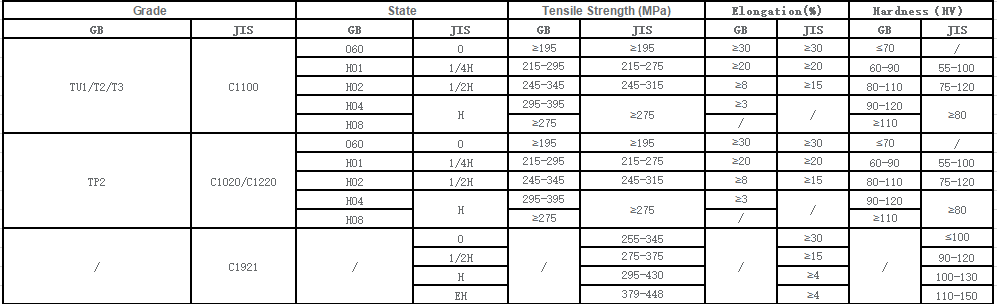

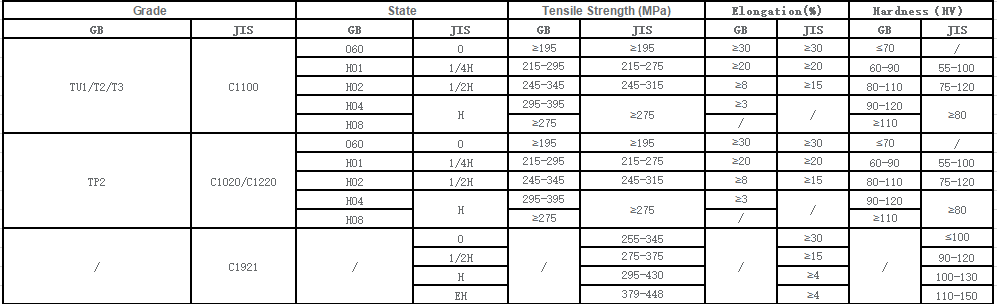

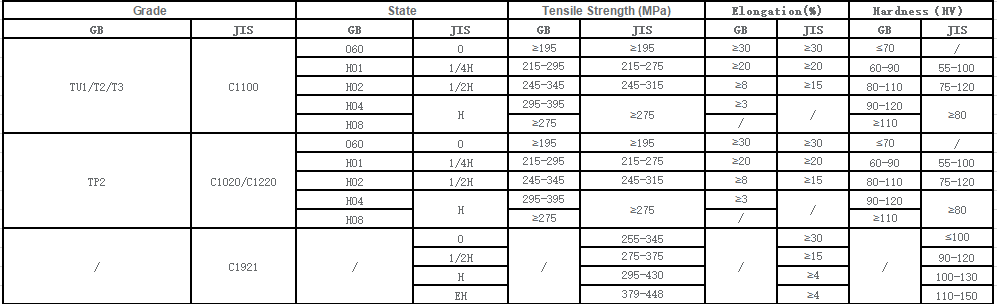

Copper Alloy Grade Comparison Table

Rolled Copper Strip Production Method and Process Flow

Raw Material → Horizontal Continuous Casting → Four-Sided Milling → Rough Rolling Mill → Thick Cutting → Uniform Covered Annealing → Finish Rolling Mill → Acid Washing → Uniform Covered Annealing → Minco Precision Rolling Mill → German OTTO Air Cushion Furnace → Stretching and Straightening Machine → Cutting, Slitting → Finished Product Packaging → 3D Warehouse → Shipping

Physical properties:

Excellent thermal and electrical conductivity, machinability, ductility, corrosion resistance, and weather resistance. They do not suffer from hydrogen embrittlement at high temperatures, making them ideal for high-tech electrical materials including RF cables, terminals, heat sinks, transformers, and coils.

Good thermal and electrical conductivity, machinability, ductility, formability, corrosion resistance, and weather resistance. They are widely used in RF cables, electronic stamping parts, computer heat sinks, and construction materials.

Customization to meet customer needs: JINTIAN's products have a precise thickness control between 0.15 and 7 millimeters, with widths adjusted according to customer requirements, catering to diverse application scenarios.

Strict process control: JINTIAN utilizes advanced Minco precision rolling mills and German OTTO air cushion furnaces to ensure each process meets the highest standards. The company has also established a comprehensive quality inspection system to monitor raw materials, production processes, and finished products, ensuring each copper strip meets the highest industry standards.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文