Copper bars are a vital component in electrical systems, acting as conductors to transfer electricity from one point to another. Copper is preferred due to its excellent electrical conductivity, durability, and malleability. However, when exposed to harsh environments, copper bars can experience various issues that can impact their reliability and durability. In this article, we will explore the challenges faced by copper bars in harsh environments and the measures that can be taken to ensure their long-term performance.

The challenges faced by electrical copper bars in harsh environments

Copper bars can be subjected to harsh environments such as high temperatures, humidity, corrosive chemicals, and mechanical stress. These conditions can cause the copper bars to corrode, oxidize, or develop surface defects, reducing their electrical conductivity and mechanical strength. When exposed to high temperatures, copper bars can experience thermal expansion, leading to mechanical stress and deformation. In addition, the presence of humidity or corrosive chemicals can cause the copper bars to corrode, reducing their cross-sectional area and increasing their resistance, leading to heat buildup and potential system failures.

To ensure that electrical copper bars perform optimally in harsh environments, various measures can be taken. One of the most effective measures is to use high-quality copper bars that are specifically designed for harsh environments. These bars are made of high-purity copper, which reduces the chances of corrosion, and have a thicker surface coating that protects them from mechanical damage and oxidation.

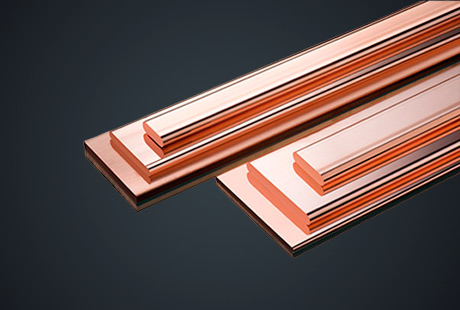

Another measure that can be taken is to use proper insulation and protective coatings to shield the copper bar electrical from corrosive chemicals, humidity, and high temperatures. Insulation materials such as PVC or epoxy can be used to prevent the copper bars, like flat copper busbar, from coming into contact with corrosive chemicals or moisture. Protective coatings such as nickel plating or tin plating can be applied to the surface of the copper bars to prevent oxidation and reduce the impact of thermal expansion.

Furthermore, regular maintenance and inspection of the electrical system can help detect any issues with the copper bars and address them before they become major problems. This can involve checking the electrical connections, tightening the bolts, and replacing any damaged or worn-out copper bars.

The benefits of electrical copper bars in electrical systems

Electrical copper bars are preferred in electrical systems due to their superior electrical conductivity, low resistance, and excellent mechanical strength. These properties make copper bars ideal for transferring high currents without experiencing significant power loss or heat buildup. Copper bars can also withstand mechanical stress and deformation without fracturing, ensuring the long-term performance and reliability of electrical systems.

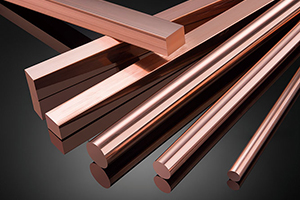

Moreover, electrical copper bars are easy to fabricate and can be shaped into various forms to fit different electrical system configurations. Copper bars can be extruded, rolled, or drawn into different shapes, including round, square, rectangular, or custom shapes, to fit specific electrical system requirements.

In addition, electrical copper bars are environmentally friendly and can be recycled with minimal energy consumption, reducing the carbon footprint and conserving natural resources. Recycling copper bars can also provide economic benefits by reducing the need for mining new copper and lowering the production costs.

Why Choose Our Electrical Copper Bars

Jintan Copper has been focusing on copper processing for over 30 years. It is a professional manufacturer of copper bars, including copper strips, copper rods, irregular copper strips, and electrical copper wire billets. The company has introduced advanced equipment and testing instruments from Germany, Japan, and the United States, and has an advanced production line, strong technical force, and complete testing facilities. The company has obtained ISO9001:2008 quality system certification and ISO14001:2004 environmental system certification. The products meet the national standards such as GB/T 3953-2009 and GB/T 2529-2005. The company has production bases in Zhejiang Ningbo, Guangdong, and Jiangsu.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文