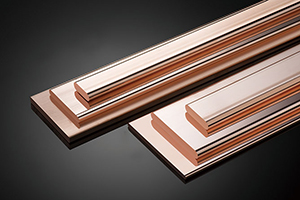

End feed fittings are vital components in plumbing installations. They are commonly used to join copper pipes together, ensuring a secure and leak-free connection. Soldering end feed fittings requires a certain level of skill and precision, as any mistakes can lead to costly repairs and potential water damage. In this blog post, we will explore the art of soldering end feed fittings, providing you with valuable tips and techniques to achieve professional results.

Preparing the Pipes and Fittings

Before attempting to solder end feed fittings, it is crucial to prepare the pipes and fittings properly. This involves ensuring they are clean and free from any contaminants. Begin by cutting the pipes to the desired length using a suitable pipe cutter. Next, use a pipe reamer or abrasive cloth to remove any burrs or rough edges. This step is essential as it ensures a smooth surface for the fitting to sit flush against the pipe, promoting a better connection.

Applying Flux

Flux is a crucial component in the soldering process as it helps to promote the flow of solder and prevent oxidation. It is important to apply flux to both the inside of the fitting and the outside of the pipe. Use a flux brush or solder wire to evenly coat the surface, ensuring complete coverage. Be careful not to over-apply flux, as excessive amounts can lead to messy joints and compromised connections.

Heating and Soldering

Once the pipes and fittings are prepared and flux is applied, it's time to heat and solder. Start by heating the fitting using a propane torch or suitable heat source. Move the flame around the fitting, ensuring even heat distribution. The heat should be sufficient to melt the solder when applied to the joint but not too hot that it causes damage or discoloration.

Once the fitting reaches the correct temperature, touch the end of the solder wire to the joint and allow it to melt and flow around the fitting. As the solder liquefies, it will be drawn into the joint, creating a strong and reliable connection. Be cautious not to apply too much solder, as excess solder can result in weak joints or blockages in the pipe.

Cooling and Inspection

After soldering, it is essential to allow the joint to cool and inspect the connection. Avoid moving or disturbing the joint until it has completely cooled, as this can lead to weakened connections. Once cooled, visually inspect the joint for any signs of imperfections or gaps. A properly soldered joint should have a smooth and consistent appearance with no visible gaps or irregularities.

In conclusion, soldering end feed fittings is an essential skill for any plumber or DIY enthusiast. By following the proper techniques and taking the necessary precautions, you can achieve professional results and ensure secure and reliable plumbing connections. Remember to properly prepare the pipes and fittings, apply flux evenly, heat and solder with care, and inspect the joints after cooling. With practice, patience, and attention to detail, you can master the art of soldering end feed fittings and tackle your plumbing projects with confidence.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文