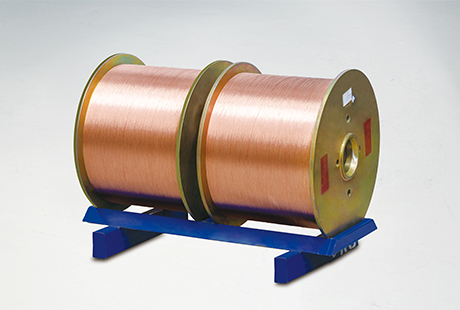

When it comes to electrical applications, choosing the right magnet wire is crucial. The performance and efficiency of electrical devices heavily rely on the selection of appropriate wire. Square magnet wire, also known as rectangular magnet wire, is a popular choice due to its unique characteristics and versatility. In this blog post, we will discuss the factors that influence the selection of square magnet wire.

Temperature Rating

One of the primary considerations when choosing magnet wire is the temperature rating. Square magnet wire is designed to have excellent thermal properties, making it suitable for applications that require high-temperature resistance. It can withstand extreme heat conditions without degrading its electrical and mechanical properties, ensuring reliable performance even in demanding environments. The temperature rating of square magnet wire depends on the insulation material used, and it is essential to select a wire with a rating appropriate for the application's operating temperature.

Insulation Material

The insulation material used in square magnet wire plays a crucial role in determining its electrical and mechanical properties. Different applications require specific insulation materials to meet their unique requirements. Commonly used insulation materials for square magnet wire include polyurethane (PU), polyamide (nylon), polyester, polyimide (kapton), and polyvinyl formal (Formvar). Each material offers distinct advantages and disadvantages, and the selection should be based on factors such as electrical conductivity, temperature resistance, chemical resistance, and mechanical flexibility.

Wire Size

The size of square magnet wire is another important consideration. The wire size determines the current-carrying capacity, voltage rating, and overall performance of the electrical device. The American Wire Gauge (AWG) system is commonly used to determine the wire size, where higher gauge numbers represent smaller wire sizes. It is crucial to select a wire size that can handle the expected current load without overheating or excessive voltage drop. Square magnet wire with larger wire sizes generally has higher current-carrying capacity but may be less flexible.

Magnetic and Electrical Properties

The magnetic and electrical properties of square magnet wire significantly impact its suitability for specific applications. The magnetic properties, such as magnetic flux density and inductance, determine its effectiveness in generating or transmitting magnetic fields. square magnet wire is known for its excellent magnetic properties, allowing for efficient energy transfer in electrical devices. The electrical properties, including conductivity, insulation resistance, and dielectric strength, influence the wire's ability to transmit and resist electrical currents. Optimal electrical properties ensure minimal power loss and improved overall efficiency.

In conclusion, several factors influence the selection of square magnet wire for electrical applications. The temperature rating, insulation material, wire size, and magnetic and electrical properties are crucial considerations that determine the wire's suitability for specific applications. As one of the reliable magnet wire manufacturers, our company's square magnet wire is highly favored for its unique characteristics and versatility, attributed to its excellent thermal conductivity, wide range of insulation materials, various wire sizes, and exceptional magnetic and electrical properties. By carefully considering these factors, engineers and designers can select the most suitable square magnet wire for their applications, ensuring optimal performance, reliability, and efficiency.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文