Understanding LED Copper Tapes' Applications

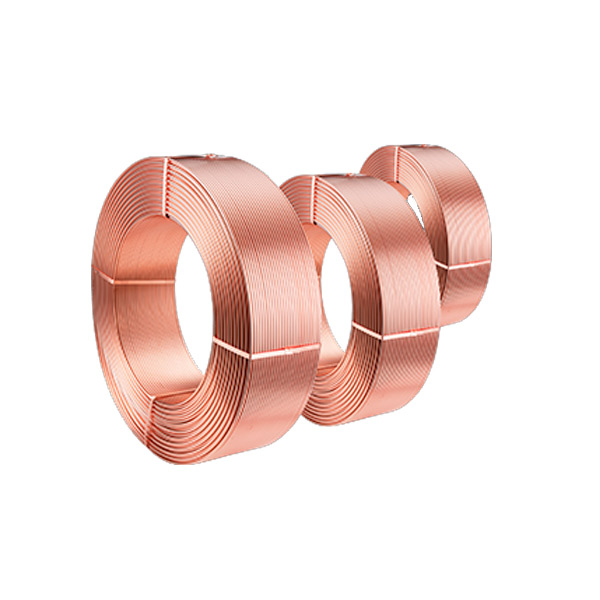

LED copper tapes play a crucial role in connecting and conducting electricity in the realm of LED lights. Their primary function is to link LED chips and circuit boards, facilitating the smooth flow of electrical current. This ensures the continuous illumination of LED beads, allowing LED light strips to operate stably. In narrow spaces or curved designs, copper tapes serve as flexible conductive connectors. Their application in LED fixtures ensures the close connection of LED chips and circuit boards, ensuring the smooth transmission of electric current and facilitating the assembly and debugging of lighting fixtures.

Installation Considerations for LED Copper Tapes

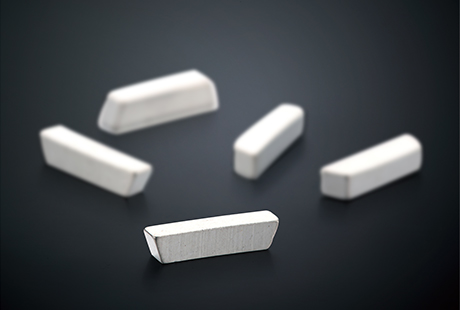

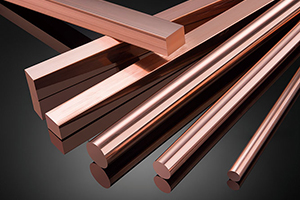

Selecting Suitable Copper Tapes: Ensure the chosen copper tapes align with the design requirements of LED fixtures. Reputable manufacturers like Jintian Copper, with over 30 years of experience, offer a range of copper tape products, including purple copper tape (C1100, C1020, C1220), tin phosphor bronze tape (C5191, C5071, C5111, C5210), brass tape (C2801, C2680, C2600), lead frame copper tape (C1921), and recycled copper tape (JT11050).

Cleanliness Matters: Before installing copper tapes, clean the surface of the LED fixture thoroughly to remove dust and impurities. This enhances the contact area between the copper tape and the LED fixture, ensuring a reliable connection.

Precise Positioning: During installation, ensure the correct positioning of the copper tape between the LED chip and the circuit board. Properly align the copper tape with the chip and board, avoiding misplacement or short-circuit issues.

Avoid Excessive Bending: During installation, prevent excessive bending and stretching of copper tapes. Over-bending may lead to damage or breakage, affecting current transmission and connection quality. Try to keep the bending within the tape's tolerance limits.

Why Choose Jintian Copper's Copper Tapes? Advantages Explained

Excellent Conductivity: LED copper tapes from Jintian Copper exhibit high conductivity, ensuring stable current transmission, reducing resistance loss, and improving the efficiency of LED devices.

Outstanding Thermal Conductivity: With superior thermal conductivity, Jintian Copper's LED copper tapes rapidly dissipate the heat generated by LED chips, maintaining a low-temperature operating state. This enhances the heat dissipation effectiveness and lifespan of LED fixtures.

Strength and Reliability: Jintian's LED copper tapes possess high strength, withstanding tension and stress without deformation or breakage. They also feature excellent oxidation resistance and corrosion resistance, maintaining stable connection quality for an extended period and ensuring stable operation in various harsh environments.

Plasticity and Processability: jintian's LED copper tapes are easy to process and shape, allowing for bending, cutting, and welding according to different LED fixture design requirements. This flexibility in application contributes to the versatile use of copper tapes in the connection parts of LED fixtures.

Jintian Copper is a nationally renowned copper tape manufacturer supporting domestic and international trade. With its own research and development institution, Jintian can assist high-end customers in customizing products. For inquiries, please contact 0574-83005999.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文