Pressure reducing valves play a crucial role in a variety of industries, including the city gas industry. Among the several materials used to manufacture these valves, brass has gained significant popularity. In this blog post, we will delve into the importance of pressure reducing valve (brass) in the city gas industry and shed light on its various applications.

Understanding Pressure Reducing Valve (Brass)

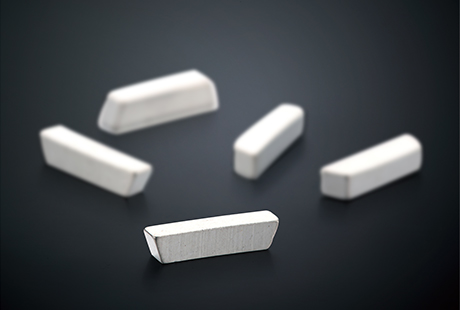

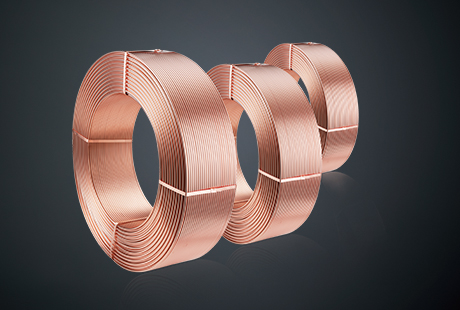

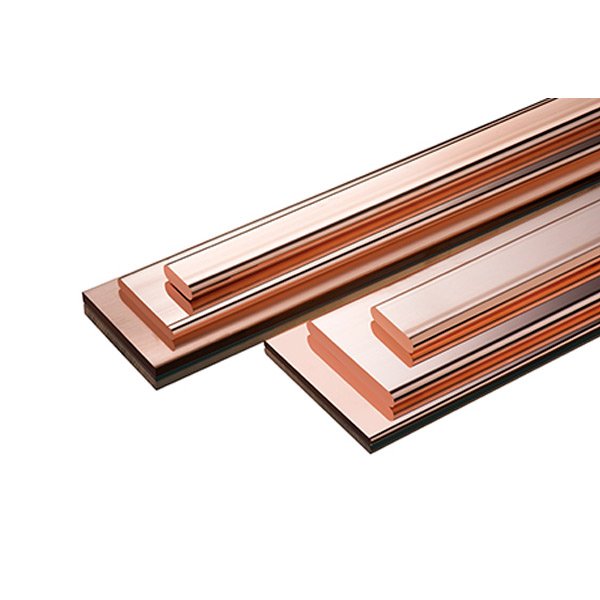

Brass is a metal alloy composed primarily of copper and zinc. It is known for its excellent corrosion resistance, durability, and ability to withstand high pressures and temperatures. These qualities make brass an ideal material for pressure reducing valves used in the city gas industry.

Efficient Control of Gas Pressure

In the city gas industry, pressure reducing valves are essential to regulate the flow of gas and maintain an optimal pressure throughout the distribution network. The use of brass in these valves ensures efficient control of gas pressure due to its inherent strength and resistance to corrosion. Brass valves can effectively handle high-pressure conditions, ensuring the safe and reliable distribution of gas to residential and commercial areas.

If you are searching for dependable brass valve supplier, don't hesitate to contact us to get the latest brass valve price!

Enhanced Longevity and Reliability

Pressure reducing valve (brass) offers enhanced longevity and reliability, which are paramount in the city gas industry. Gas pipelines and distribution systems are subject to constant wear and tear, including exposure to harsh environmental conditions. Brass valves, with their superior resistance to corrosion, minimize the risk of leakage or failure, ensuring a prolonged service life. This increases operational efficiency and reduces maintenance costs for gas companies.

Versatile Applications

Brass pressure reducing valve finds versatile applications in the city gas industry. They are commonly used in gas distribution networks, gas meters, and various gas control systems. The robust properties of brass enable these valves to withstand high pressures, making them suitable for diverse gas infrastructure requirements. Moreover, brass valves can accommodate a wide range of gas types, including natural gas, propane, and butane, making them adaptable for different gas compositions.

Environmentally Friendly Solution

Brass is known for being an environmentally friendly material. It can be recycled and reused, reducing the demand for new resources and minimizing waste. In an era where sustainability is a crucial aspect, the incorporation of pressure reducing valve (brass) aligns with eco-friendly practices. Choosing brass valves for city gas infrastructure contributes to a greener and more sustainable gas industry.

In conclusion, pressure reducing valve (brass) plays a vital role in the city gas industry. Its exceptional durability, corrosion resistance, and capability to withstand high pressures and temperatures make it an ideal material for these valves. Brass valves provide efficient control of gas pressure, enhanced longevity, and reliability, ensuring safe and reliable gas distribution. With versatile applications and an environmentally friendly nature, pressure reducing valve (brass) emerges as an indispensable component in the city gas sector. By selecting brass valves, gas companies can guarantee the longevity, efficiency, and sustainability of their gas distribution networks.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文